Chrome-plated and anodized are two common metal surface treatment processes, and they are significantly different in purpose, principle, and application scenarios. The following is a detailed comparison of these two treatment processes:

1. Definition and Principle

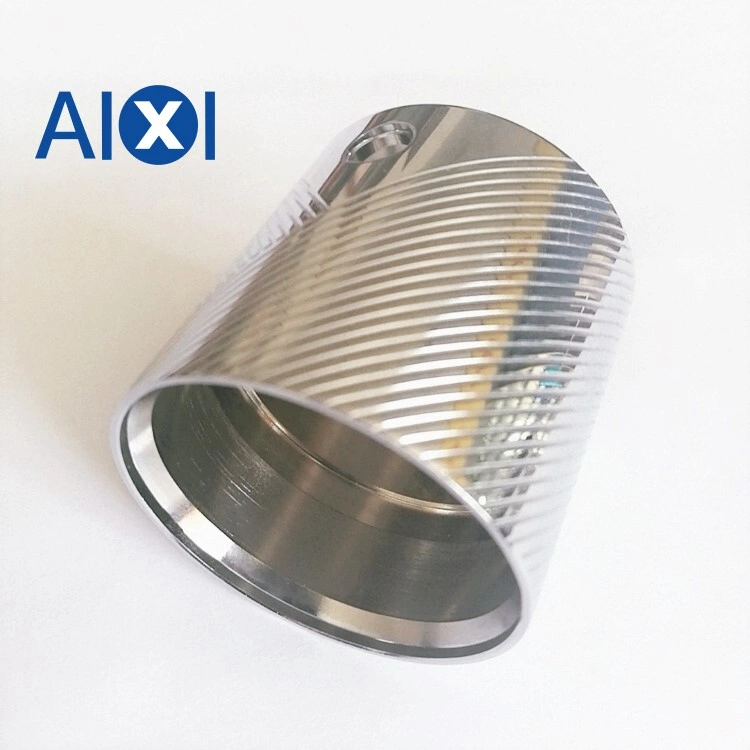

1.1. Chromium plating: Chromium plating is a process of depositing a chromium layer on a metal surface by electrolysis. In the electrolyte containing chromium ions, the chromium ions are reduced to metal chromium and deposited on the metal substrate by the action of current. The chromium layer has good corrosion resistance, hardness, and decoration, so it is widely used in automobiles, household appliances, hardware, and other fields.

1.2. Anodizing: Anodizing is a process of forming an oxide film on the metal surface by electrochemical method. In a specific electrolyte, metal acts as an anode, and through the action of current, the metal surface undergoes oxidation reaction, forming a dense oxide film. This oxide film has good corrosion resistance, insulation and wear resistance, and is often used for surface treatment of aluminum and aluminum alloys.

2. The treatment process and conditions

2.1. The chromium plating process requires plating equipment, chromium plating solution, and a power supply. During electroplating, parameters such as current density, temperature and pH value should be strictly controlled to obtain uniform chromium layer thickness and good adhesion.

2.2. The anodizing process requires anodizing equipment, electrolytes, and a power supply. In the process of anodized, it is necessary to adjust the electrolyte composition, temperature, current density and other parameters to obtain the required oxide film thickness and performance.

3. The treatment effect and performance

3.1. The chromium plating layer has high hardness and wear resistance, which can provide good scratch resistance and wear resistance. At the same time, the chromium layer also has excellent corrosion resistance, which can effectively resist oxidation, corrosion, and chemical erosion. In addition, the chrome-plated layer also has rich color choices, which can achieve a variety of decorative effects.

3.2. The anodic oxide film has good corrosion resistance, insulation and wear resistance. Because the oxide film is porous, it can be further sealed to improve its corrosion resistance. In addition, the anodic oxide film also has good adsorption performance, which can adsorb dyes, lubricating oil and other substances to achieve a variety of surface decoration effects.

4. Application fields and limitations

1. Chromium plating is widely used in automobiles, household appliances, hardware, and other fields, especially where high corrosion resistance, hardness, and decoration are needed. However, the wastewater and gas produced in the chromium plating process cause certain environmental pollution, so we need to pay attention to environmental protection when using it.

2. Anodizing is mainly used for the surface treatment of aluminum and aluminum alloys, especially where corrosion resistance, insulation, and wear resistance need to be improved. However, the anodized process requires higher metal substrates, such as surface roughness and impurity content, which will affect the quality and performance of the oxide film. In addition, the choice of thickness and color of anodic oxide film is relatively limited, which may not meet all decorative requirements.

3. Different treatment methods Electroplating takes the material to be electroplated as the cathode, the same metal material as the plating metal as the anode (or insoluble anode), and the electrolyte is a solution containing plating metal ions. A certain current is input between the anode and cathode. The coating material is different from the material to be electroplated, such as beryllium copper nickel plating, beryllium copper as substrate, and nickel as coating. Anodizing uses chemical or electrochemical treatment to form a coating containing the metal component on the metal surface. The material to be treated is used as an anode, and a film is formed on the surface of the anode by an applied current in a specific electrolyte. For example, when the aluminum alloy is oxidized, a thin film of alumina is formed on the surface of the aluminum alloy. Alumina is chemically stable, will not be oxidized again, will not be corroded by acid, and can be dyed into various colors.

4. Different processing objects The objects treated by the electroplating method are mainly metals or nonmetals. The commonly used electroplating coating metals are nickel, chromium, tin, copper, silver, and gold. That is to say, it is often said that nickel plating, chromium plating, gold plating, and so on. Anodizing treatment is a method of metal surface treatment. Most metal materials (such as stainless steel, zinc alloy, aluminum alloy, magnesium alloy, copper alloy, and titanium alloy) can be anodized in a suitable electrolyte.

5. Different treatment principles Electroplating is that electroplating material is used as cathode, and anodized zone treatment material is used as anode. Electroplating is due to the charge effect; metal anode ions move to the cathode, and electrons are obtained at the cathode and deposited on the material to be plated. At the same time, the metal of the anode is dissolved, and the metal ions in the electrolyte are continuously replenished.

Firstly, the electroplating solution has six elements: main salt, additional salt, complexing agent, buffer, anode activator and additive. Electroplating principle includes four aspects: electroplating solution, electroplating reaction, electrode and reaction principle, and metal electrodeposition process.

Anodizing is to control the formation of an oxide layer by electrochemical method to prevent further oxidation of aluminum and increase the mechanical properties of the surface. Generally speaking, aluminum or aluminum alloy is used as an anode, and a lead plate is selected as a cathode. Aluminum and lead plates are put together in an aqueous solution, which contains sulfuric acid, oxalic acid, chromic acid, etc., and electrolyzed to form an oxide film on the surfaces of aluminum and lead plate.

Among these acids, anodized with sulfuric acid is widely used. Aluminum alloy anodizing technology is widely used and successful at present. Aluminum alloy anodizing can greatly improve the surface hardness, wear resistance, and other indicators. There are a lot of micro.

5. Conclusion

To sum up, there are obvious differences between chromium plating and anodizing in terms of definition, principle, treatment process, treatment effect, and application field. Chromium plating is mainly used to improve the corrosion resistance, hardness, and decoration of metal surfaces, while anodized is mainly used to improve the corrosion resistance, insulation, and wear resistance of aluminum and aluminum alloys. When selecting the metal surface treatment process, we should comprehensively consider the specific needs and metal materials.

In addition, with the increasing awareness of environmental protection and the development of new technologies, surface treatment processes such as chromium plating and anodization are constantly improving and optimizing. For example, researchers are developing environment-friendly chromium plating processes and new anodized technology to reduce environmental pollution and improve treatment effects. In the future, with continuous progress and innovation in science and technology, the metal surface treatment process will develop in a more environmentally friendly, efficient and diversified direction.

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español