What Is CNC Prototyping?

CNC aluminum prototyping is a popular method for creating prototypes. The process is mostly automated and requires little manual work, but a well-experienced user can still be an invaluable asset in creating a high-quality part. An experienced user will also be aware of the intricacies of different materials, as well as the most common mistakes that are likely to occur. They will also be able to offer guidance and help ensure that the parts are exactly what you require.

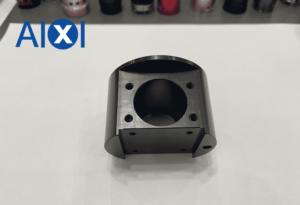

CNC aluminum prototyping offers several key benefits. Compared to outsourcing, it is much cheaper. Not only does it save on shipping costs, but it also allows for rework on short notice, avoiding the cost of making a new part. Consider an example of an electronics housing. If you’re looking to prototype a new product, you can use CNC aluminum prototyping to create a high-quality part without the hassle of a long wait.

CNC prototyping provides the best results possible. It is a highly effective manufacturing process and can handle a wide variety of aluminum alloys. It begins with a 3D CAD model. It is easy to change the design after the first prototype is complete. The benefits of CNC machining are endless. It’s a great tool for prototypes and can also be used for production. Aside from being a useful tool for prototypes, CNC machining also allows for easy changeovers.

CNC prototyping requires the expertise of top-notch engineers and a highly skilled team of technicians. However, CNC prototyping is not for everyone. If you need a prototype to test your product, Rapid Prototyping is a better option. A CNC machine will bring your 3D model to life within a matter of hours, compared to weeks or months with other prototyping techniques. This will help you see if your product is a good fit before you commit to a full-scale production run.

Benefits of CNC Prototyping

The benefits of CNC prototyping include fast production. CNC prototype machining requires limited human input and eliminates manual labor. While it’s true that CNC machining is more efficient than manual production, you can’t sacrifice quality. A CNC prototype can be created faster than any human worker. If you want to avoid delays, it’s best to have an experienced user oversee the process. These professionals will know the mistakes to avoid. In addition, they’ll be able to give you advice on how to avoid them and ensure that your prototypes are produced to the highest quality.

The benefits of CNC prototyping are immense. Typically, you can design a prototype using a 3D drawing, then use a CNC milling machine to create it. A CNC milling machine will create a part with a circular cross-section, while a CNC laser will produce a 3D surface design. CNC milling can save a tremendous amount of time and money. When you have a new product idea, it’s crucial to make a prototype so you can test it before committing to a mold.

CNC machining is often referred to as rapid prototyping. In this process, your prototype is manufactured very quickly and cheaply. Depending on the size of your project, you may want to consider a CNC machining machine. Stainless steel is expensive, so cheaper plastics and aluminum are best for prototypes. You’ll be surprised by how versatile CNC machining is.

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español