With the continuous advancement of science and technology, there are more and more kinds of aluminum alloy surface treatment processes.

The appearance of each treatment process is different, and its use is also different.

What are the surface treatment processes of aluminum alloy

1. Highlight cutting

Use a precision engraving machine to cut some parts of the aluminum alloy surface, so that these cutting surfaces show bright areas.

This kind of processing technology is generally used in mobile phones and high-end TVs, especially those high-end TVs use this technology, so that the appearance of the TV becomes more fashionable, and it also presents a sharp sense of technology.

2. Sandblasting

This process uses the impact of high-speed sand flow to clean and roughen the surface of the aluminum alloy, so that the surface of the aluminum alloy can obtain a certain degree of cleanliness and different degrees of roughness.

After sandblasting of aluminum alloy, its mechanical properties can be improved, thereby improving the fatigue resistance of aluminum alloy products, and at the same time increasing the adhesion and durability of aluminum alloy products and surface coatings.

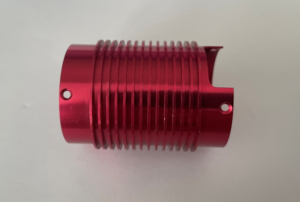

3. Hairline

This process refers to the use of sandpaper to repeatedly scrape the aluminum alloy surface until the lines are scraped.

There are many types of wire drawing, such as: straight, chaotic, threaded, twisted and so on. After the drawing process of aluminum alloy, each line can be seen very clearly on its surface, and at the same time, the metal matte of the aluminum alloy product will show a fine hairline luster, which makes the aluminum alloy product more fashionable. And a sense of technology.

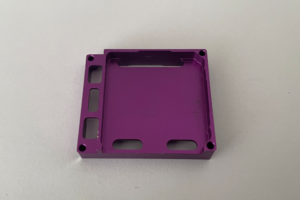

4. Polishing

This process refers to the use of mechanical, chemical or electrochemical methods to polish the surface of the aluminum alloy product, thereby reducing the surface roughness of the aluminum alloy product, and making the surface of the aluminum alloy product more smooth and bright.

The polished aluminum alloy product has a surface effect close to the mirror effect of stainless steel, which can give a very high-end and fashionable visual effect.

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español