1 Thread milling method

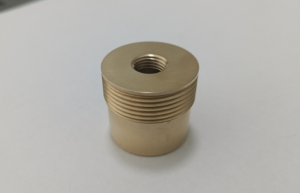

CNC machining centers can use thread milling tools to directly process threads. This is also a common processing solution in the market. It is widely used in more complex thread processing and large-hole thread processing operations, and the advantages are also obvious.

The thread milling method under the CNC machining mode can obtain high machining accuracy while ensuring a fairly fast machining speed. For thread decontamination tool applications, the same tool can be used for right-handed or left-handed threads. Because the thread milling method has more prominent economic benefits, it has become a commonly used processing technology in the current CNC machining center.

The thread milling method can also be applied to the processing of different materials and complex materials, such as the processing of copper or stainless steel. The thread milling method can ensure the processing accuracy.

2 Tap processing method

The tap machining method is also a common CNC machining process, which is generally suitable for small diameter thread machining, but the accuracy is relatively poor. Therefore, if you encounter processing requirements that require high precision, you should avoid the use of tap processing.

In order to ensure the application of tap processing method, the appropriate drill hole should be selected with the corresponding drill diameter to ensure that the upper limit of the diameter tolerance of the threaded bottom hole can be coordinated with each other. This can effectively reduce the workload of tap processing in the follow-up work, and at the same time Reduce the probability of tap damage in actual processing by tap processing method.

The damage to the tap is mainly due to the difficulty in forming a coordinated relationship when the tap is in contact with the processed material. This phenomenon can easily cause damage to the tap or decrease in durability. At present, in actual production, through-hole taps and blind-hole taps are widely used. In production, a reasonable choice should be made in combination with the needs of thread processing.

3 Pick-and-click processing method

The pick-and-click method is rarely used in actual production and processing. It is generally used as an emergency method when there are no thread milling tools and taps. Generally used in the case of box parts that need to make larger threaded holes, it is necessary to use threaded turning tools and boring bars for boring processing.

In the process of processing, we must first pay attention to the rotation speed of the spindle, and effective control should be carried out for the delays that easily occur in the early stage of the spindle rotation, so as not to affect the processing of the thread due to the improper rotation speed. In the processing of multi-toolholders, it is necessary to ensure the position between the toolholders, to ensure that the corresponding positions of the toolholders and the grooves are consistent, to avoid the phenomenon of random buckling, which affects the processing effect of the final product. In the processing method, it is necessary to avoid one-cut picking, and try to multi-cut operations to better improve the effect of thread processing. In actual production, due to low efficiency, it is not suitable for large-scale promotion and application in CNC machining, and can only be used as an emergency backup plan.

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español