Top Aluminum – Cost-effective Processing of Aluminum Parts

If you are looking for a high-quality, high-precision, and fast aluminum CNC machining product manufacturer. You can trust Ashe to be your best choice. We have several high-end five-axis linkage CNC machine tools (a machine tool with high technological content, high precision, and dedicated to processing complex curved surfaces) and dozens of four-axis and three-axis CNC machining machines. A strong team of engineers can quickly produce drawings through samples and quickly complete prototype verification. Fully certified aluminum CNC machining processes (CNC Aluminum Milling, CNC Aluminum Turning, CNC Aluminum Drilling) for rapid prototyping and low-volume production of end-use components or complete products.

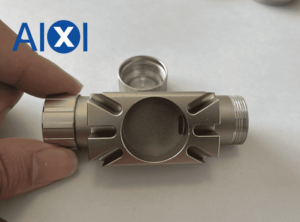

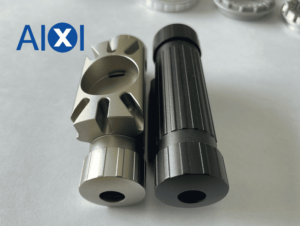

CNC Aluminum Machining

Why choose aluminum profiles for CNC machining?

First of all, aluminum is the third most abundant element in the earth’s crust, after oxygen and silicon, and is a relatively new industrial metal. With its excellent thermal properties and machinability, it has quickly become an important industrial material, and it is also a common CNC machining material; aluminum and aluminum alloys themselves are a light, non-magnetic silver metal that can be formed into any shape metal parts and is therefore the material of choice in most areas of manufacturing across numerous industries.

Advantages of aluminum and aluminum alloy materials:

- Non-toxic, requires less heat than stainless steel or cast iron, and heats quickly and evenly.

- Aluminum contributes to building corrosion-resistant and low-maintenance buildings, and aluminum products are used for new construction and renovation.

- The combination of light weight, strength and ductility makes aluminum CNC milling parts an ideal material for transportation applications.

- Non-magnetic, non-flammable

- Low temperature resistance

Advantages of CNC machining of aluminum and aluminum alloy materials:

- High efficiency, short production cycle

- High precision, which can meet the production needs of various high-precision parts

- Strong flexibility, can realize different processing methods according to different product design requirements and processing parameters, and has strong customizability

Different types of common aluminum materials:

Aluminum 2024, Aluminum 5052, Aluminum 6063, Aluminum 6061, Aluminum 7050, Aluminum 7075, Aluminum MIC-6

Surface treatment:

- Color: natural color, black, blue, green and different colors according to your requirements

- Process: anodizing, sand blasting, shot peening, polishing, oxidation, electrophoresis, chromate, powder coating and painting

Aluminum profile CNC processing technology:

CNC aluminum turning, CNC aluminum milling, CNC aluminum drilling

Aluminum profile CNC processing application industry:

Aluminum CNC parts can be applied in automotive, electrical, military, medical, aircraft, power generation, aerospace and industrial engineering

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español