China Sheet Metal Fabrication Service – AIXI

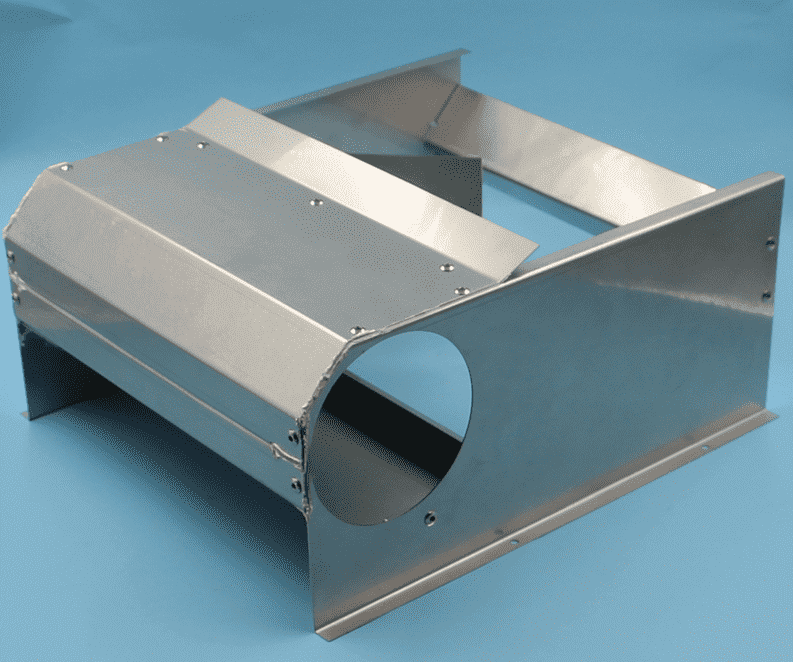

We usually call sheet metal fabrication for some bent metal sheets. At present, our company’s most produced sheet metal parts are audio products, shells, internal brackets, and prototypes. Our factory’s processing speed is very fast, and the price of sheet metal fabrication is relatively low compared to other industries.

Of course, many automotive and electronic product industries also use sheet metal fabrication services. Many metal products in the most popular 5G servers are also produced by sheet metal and stamping. Sheet metal is mainly produced in small batches, and stamping can be produced in large batches.

AIXI sheet metal fabrication service supplier has sheet metal workshops and CNC workshops to provide one-stop processing services. Contact us for more information.

Get a Quote

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español