Rapid Prototyping | Production-Manufacturing Services

At AIXI, making our customers’ designs a high-quality product is the goal we have been pursuing and will never change. Our company can provide comprehensive services, precision machining, 3D printing, sheet metal, injection molding from prototype processing to surface treatment, extrusion, silicone mold, surface treatment, most of our engineers are more than 10 years of industry experience, we are waiting for you at AIXI, give us your design, we will give you a free quote.

CNC Machining

We have 3/4/5 axis cnc processing machines, as well as turning and milling machines, which can provide many prototypes for simultaneous processing. We also do EDM and wire cutting,drilling services.

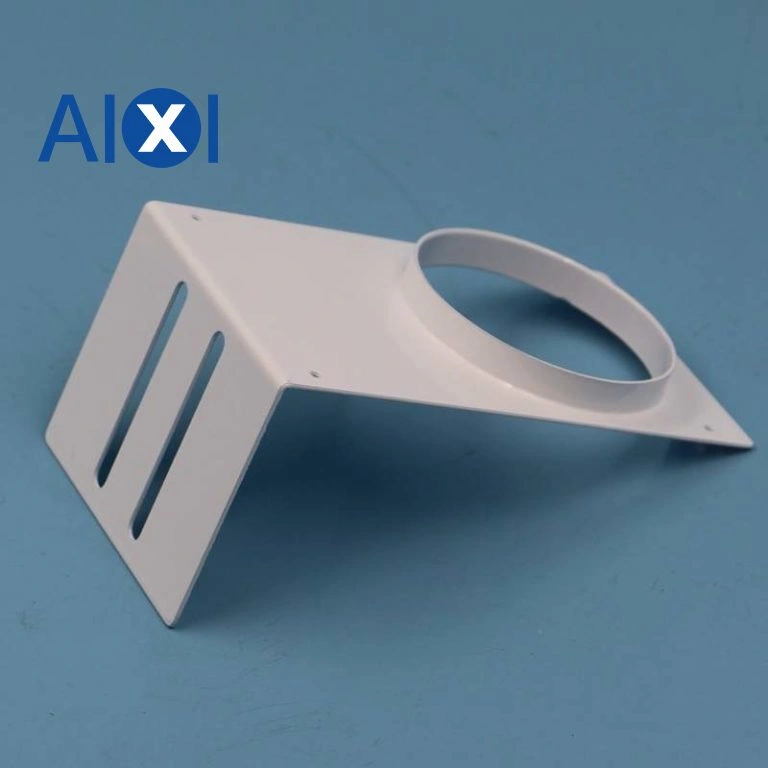

Sheet Metal Services

sheet metal prototyping services offer a fast and cost-effective solution for your projects. Services including bending, punching, cutting standard gauge metal for both prototypes and low volume production runs.

Extrusion Services

Common aluminum extrusion and plastic extrusion, the material is transformed into the shape of the product you design through the extrusion process, usually also CNC processing after extrusion.

Surface Finishing

For some common surface treatments, anodizing, sandblasting, wire drawing, polishing, dusting, painting, electroplating, laser logo, silk screen, heat treatment, etc., we all do very well.

3D Printing

high-quality 3D printing (additive manufacturing) services, including FDM, SLA, SLS and SLM. This allows for the 3D printing of plastics and metals, and provides options for both prototyping and production.

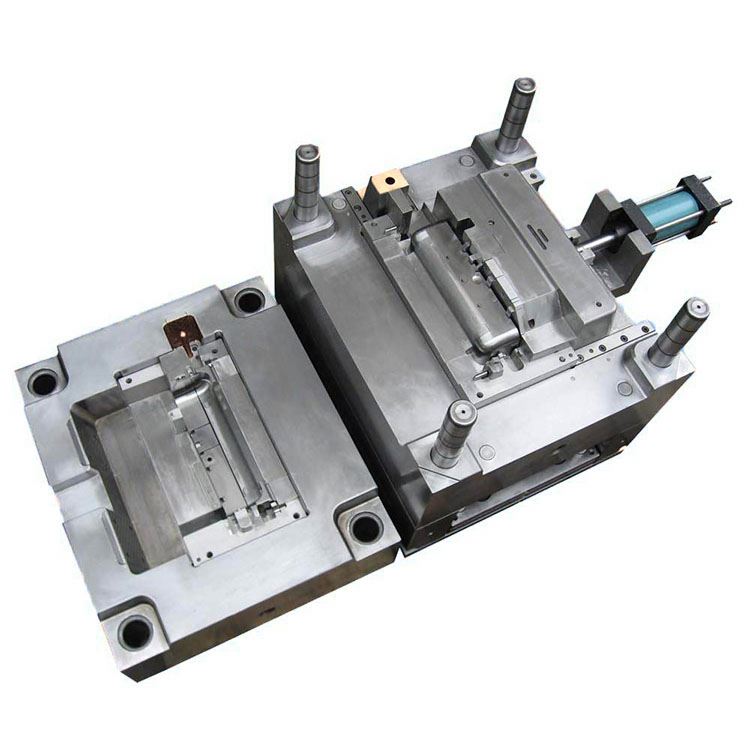

Injection Molding

Compared with silicone molds, injection molding is very advantageous for high-volume production. When paying for one mold, the unit price of the batch will be very cheap. It can make more than 150,000+pcs.

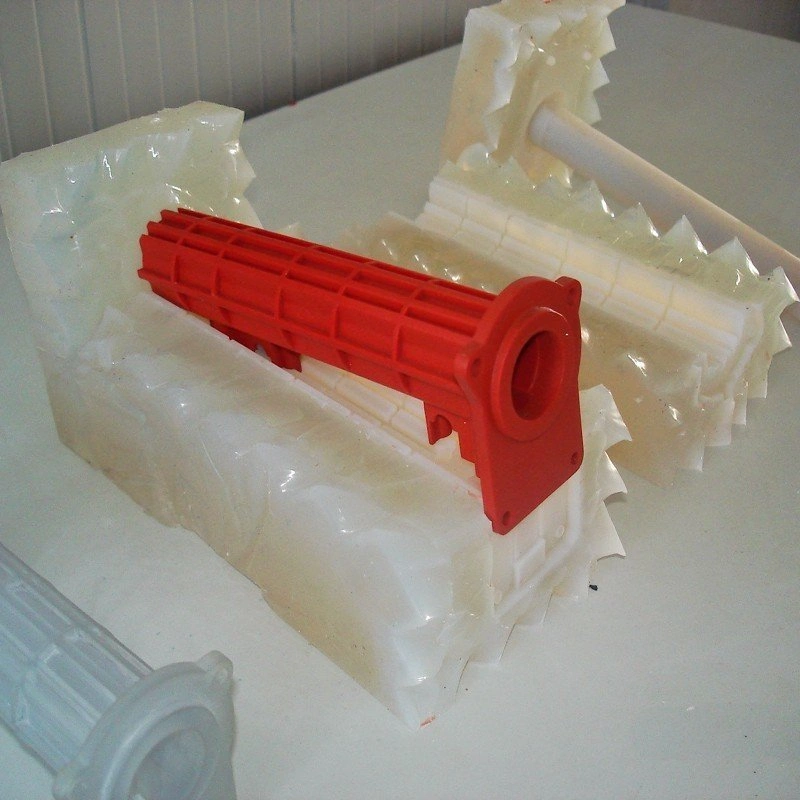

Vacuum Casting

Vacuum casting is a great way to make rigid or flexible parts, and is ideal for prototypes, testing, concept proofing and display demos. These parts can be made from hundreds of casting polymers.

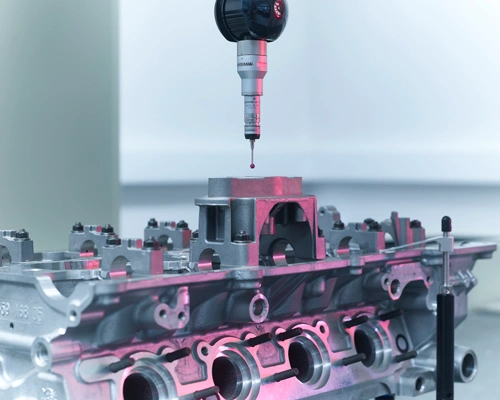

Quality Assurance

Our quality assurance starts from incoming materials inspection, then first article and in-process inspection, and final inspection and testing with reports and certifications before shipping.

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español