In recent years, PP fiber reinforced materials have developed rapidly in the modified plastics industry, and most of the glass fiber reinforced materials used in the automotive field are PP substrates. With the improvement of plastic modification technology and the needs of the development of the automotive industry, the development trend of long glass fiber reinforced materials has expanded from PP to PA, and the fiber addition of PA materials has begun to be active in the automotive field.

PA material has excellent mechanical properties, outstanding corrosion resistance, oil resistance, heat resistance, high modulus, etc. After being reinforced with long glass fiber, the strength, impact resistance, energy absorption rate and other aspects have been very good. Greatly improved.

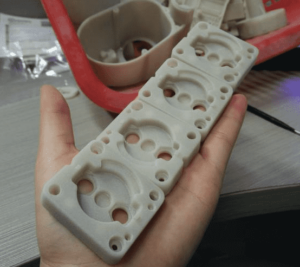

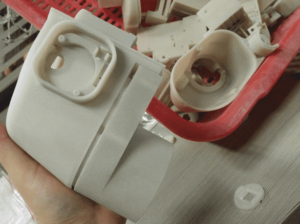

PA material plus fiber can be used in the automotive field. PA material with fiber can replace metal in many occasions. The injection molded products of glass fiber reinforced materials have high glass fiber length retention rate and good glass fiber distribution. At the same time, glass fiber penetrates the matrix resin as a reinforced skeleton, so that the product has high specific strength, high rigidity, high impact resistance, high dimensional stability, High temperature resistance, low warpage, excellent creep resistance, and thermal expansion coefficient comparable to metal materials, so it has a wide range of applications in the automotive field.

Application of PA material plus fiber in the automotive field PA material plus fiber can be applied to instrument frame panels, door assemblies, front-end components, body door modules, roof panels, seat frames, handle levers, battery brackets, tire frames, cooling For fans and frames, LFT-PA material not only has the functional characteristics of metal, but also reduces the weight of the car, so that the car can be lightweight.

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español