Is Delrin Easy To Machine?

If you’re new to the world of thermoplastics, you’ve likely been wondering if Delrin is easy to machine. This high-strength thermoplastic material has a high degree of dimensional stability, is hydrocarbon resistant, and is low-friction. If you’re interested in learning more about Delrin, you’ve come to the right place. Learn how to machine Delrin to produce parts for your business, or just want to learn more about this unique material.

Delrin Is A High-Strength Thermoplastic

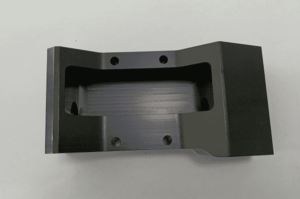

One of the primary benefits of Delrin is that it is easy to machine, with the materials being extremely durable. Delrin is available in sheet and rod form, and the parts can be machined to exacting specifications using standard machining processes. While it is highly durable, centerline porosity may occur in some parts. This condition can compromise structural integrity by providing pathways for liquids, gases, and bacteria.

It Has Excellent Dimensional Stability

A semicrystalline engineering grade thermoplastic, Delrin is used widely for precision parts, and it offers excellent sliding and dimensional stability. Delrin also has excellent mechanical properties, including high strength and a wide operating temperature range. It is an easy material to machine and is highly resistant to abrasion, tearing, and other types of wear. It is also an easy material to machine and will not lose its shape during the process.

It Is Resistant To Hydrocarbons

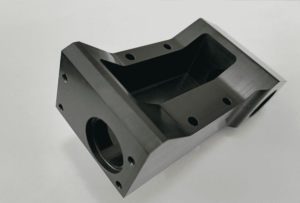

Its properties include high stiffness, resistance to impact and high pressure, and ease of machineability. These properties make Delrin perfect for use in load-bearing and high-impact applications. It retains its original shape even under high temperatures, extreme pressure and varying humidity. This makes it valuable in dimensionally stable applications such as valves, pumps and plumbing fixtures. Here are some examples of Delrin applications.

It Is A Low-Friction Material

Delrin is a semi-crystalline acetal homopolymer thermoplastic. It has a tensile strength between 6,000 and 22,000 PSI, which means that it is resistant to breaking under tension. High-strength Delrin is often used in applications that must withstand high levels of stress. It is a good option for high-stress environments.

It Is A Free-Cutting Plastic

As a free-cutting thermoplastic, Delrin has excellent dimensional stability and outstanding toughness. This material can withstand high stress and sudden impacts without breaking. This makes it ideal for machining applications and can be used in a variety of industries. Some of the common applications for Delrin include mechanical and electrical components, medical equipment, and aircraft parts. This article will discuss some of the unique characteristics of this material.

It Is A Good Insulator

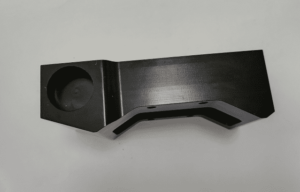

Delrin is an excellent material for rapid prototyping. It is easy to machine and is suitable for injection molding and 3D printing. Its insulating and mechanical properties make it an excellent material for electronic components. It also resists moisture and creep. It is very easy to machine and has excellent dimensional stability. It is one of the most commonly used plastic materials in rapid prototyping.

Benefits Of CNC Machining POM

CNC machining of POM can help reduce costs while boosting productivity and the quality of the end product. Its low friction properties allow it to be easily machinable and is useful for engineering-grade applications. Like POM, Teflon feels greasy and buttery to the touch. To better understand the benefits of CNC machining POM, consider these examples. Read on to learn how to maximize the efficiency of your next project.

POM is an engineering-grade plastic from the palm family that is popular for many applications. Its excellent machineability, higher strength, and superior dimensional stability make it a desirable choice for CNC machining. It is a more expensive material than ABS, but it has other advantages, including higher dimensional stability and a lower friction. Its strength and chemical resistance make it a desirable material for a number of industries.

Delrin is another popular choice for CNC plastic machining. It has excellent wear resistance, is easy to glue, and is self-lubricating. Although it does not respond to adhesives, it is easier to bond than POM copolymers. It is not self-extinguishing, so it is recommended for applications that require a low friction level. Despite its many advantages, Delrin is difficult to machine with conventional methods, and requires an experienced CNC operator.

CNC machines automate the process of machining machine tools through embedded software. CNC machines are commonly used to mill plastic and metal parts. Each object to be manufactured gets its own customized computer program, usually written in an international standard language called G-code. The machine control unit (MCU) stores these instructions and parameters in the machine. A human operator tests the program before it is run without any raw material to ensure it is accurate.

English

English Deutsch

Deutsch Français

Français 日本語

日本語