El aluminio es un material metálico con excelentes propiedades como ligereza y resistencia a la corrosión. Se ha convertido en uno de los materiales más populares en el proceso de fabricación de chapa debido a su rentabilidad y variedad de calidades. La fabricación de láminas de aluminio es el proceso de dar forma a una…

Archivos de Categoría: Servicios de chapa metálica

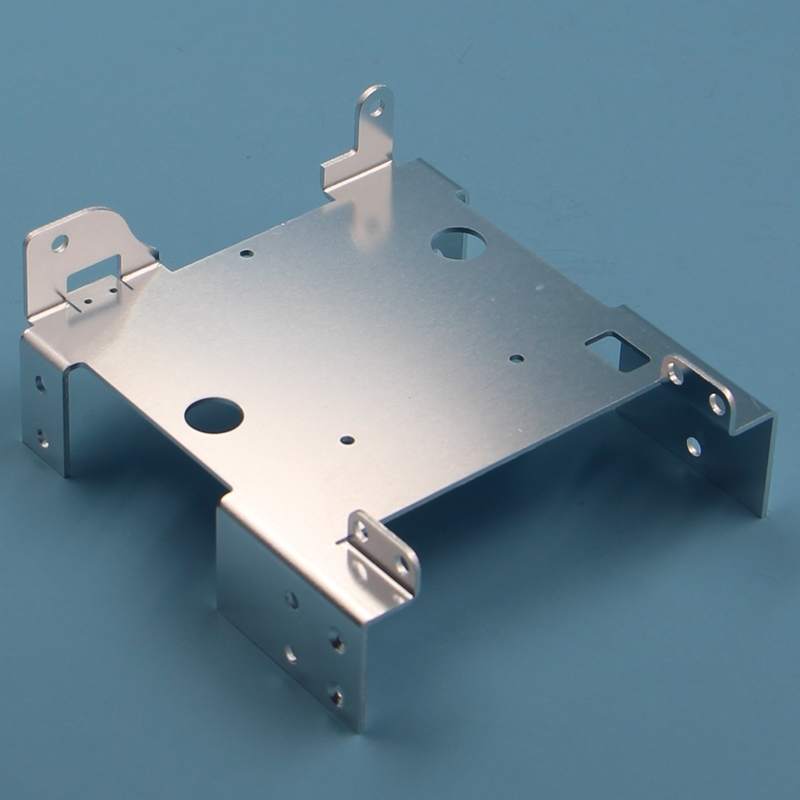

Designing the sheet metal process While meeting the functional and appearance requirements of the product, the design of the sheet metal should ensure that the stamping process is simple, the stamping mold is easy to make, the sheet metal stamping quality is high, and the dimensions are stable. After the drawings are designed and produced,…

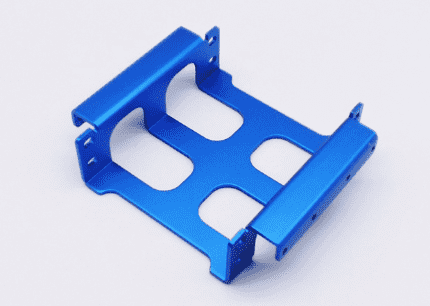

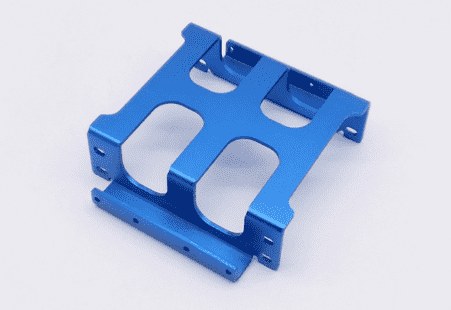

Sheet metal is a comprehensive cold working process for metal sheets usually less than 6mm, including shearing, punching, cutting, compounding, folding, riveting, splicing, forming (such as automobile bodies), etc. Sheet metal processing is called sheet metal processing. For example, plates are used to make chimneys, iron barrels, fuel tanks, ventilation ducts, elbows, large and small…

Commonly used sheet metal materials 1. Cold rolled sheet, SPCC. The most basic sheet metal material is widely used. It is used as the base material of other materials and is relatively easy to rust. 2. Electrogalvanized sheet, SECC, is widely used, and it is obtained by electroplating with cold plate as the base material,…

Metal Sheets have been part of the manufacturing industry for years. Their next-level fabrication support nurtures many real-life applications. Different types of metal sheets are available and vary in their material. Among those, steel vs. aluminum vs. brass metal sheets are top-rated. Each of these materials has unique properties. So, their sheets also offer…

Special-shaped sheet metal processing also has a high appearance rate among manufacturers of mechanical equipment. Since 2005, the development momentum of the sheet metal industry has been very rapid, and the position and weight in the market are becoming more and more important, not only to our company. In addition to the huge economic benefits,…

Sheet metal processing industry is a classic traditional industry sheet metal processing. With the successive invention of sheet metal processing in the last century by semiconductors, computers, lasers, etc., it has injected new vitality into the sheet metal processing industry, and has greatly promoted the industries of aviation, automobiles, shipbuilding, communications electronics and precision instruments…

The simplest overview of sheet metal processing is to process materials on metals with different properties. In the process of sheet metal processing, there is actually a certain demand for metal materials. Of course, this is not only necessary for the integrity of the metal sheet, but also about the metal Appearance also needs to…

1. In order to prevent broken chips from hurting people, a transparent baffle should be installed in an appropriate position. 2. When you need to use gauze to polish the surface of the workpiece, move the tool to a safe position, and be careful not to let your hands and clothes touch the surface of…

With the rapid development of sheet metal processing technology, the domestic processing technology is also changing with each passing day, and the gap between the developed countries and foreign countries is getting smaller and smaller. Many well-known foreign-funded enterprises have moved their manufacturing bases to China. Many revolutionary ideas have come. As the traditional sheet…

English

English Deutsch

Deutsch Français

Français 日本語

日本語