Can You CNC Aluminum? Can you CNC aluminum? Yes, you can. However, there are several things to keep in mind. Aluminum is extremely difficult to cut and requires high-quality tooling. Here are a few tips for cutting aluminum. First, don’t forget to lubricate the cutting tool. Aluminum will stick to the bit if it’s not…

Archivos de Categoría: Mecanizado CNC

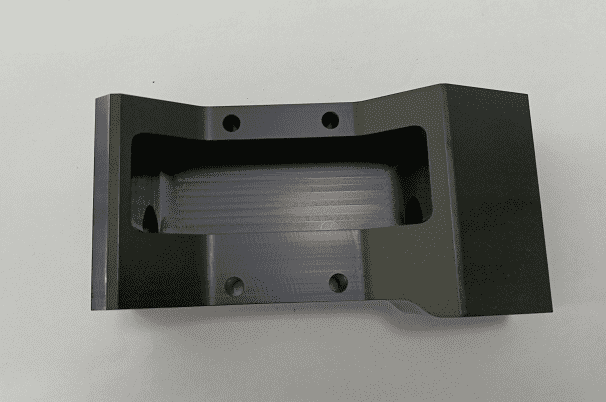

What Is CNC Prototyping? CNC aluminum prototyping is a popular method for creating prototypes. The process is mostly automated and requires little manual work, but a well-experienced user can still be an invaluable asset in creating a high-quality part. An experienced user will also be aware of the intricacies of different materials, as well as…

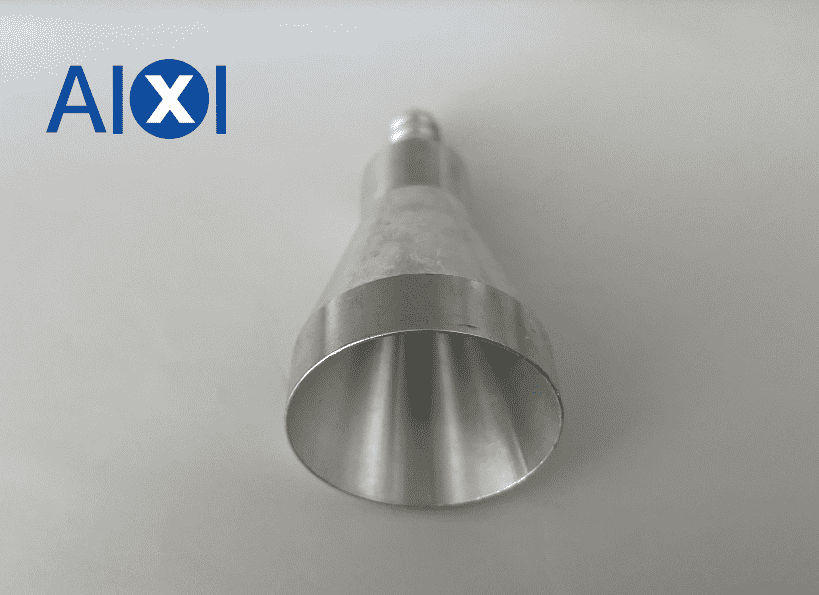

Is Aluminum A Common Prototyping Material? If you’re a product designer, you’re probably wondering, «Is aluminum a common prototyping material?» If so, you’re not alone! Aluminum is often used for prototype manufacturing due to its outstanding qualities, including corrosion resistance and strength. This makes it a highly suitable choice for various projects, from pre-production prototypes…

According our experience : 1: Quote speed If quantity lower 10 products , can’t quote within 8-10hours , it means can’t reply within working day , i think this is not real factory , most likely is a trade company , because they need wait other company quote , then quote to customer . so…

CNC precision machining can manufacture a variety of complex parts with high precision. Machines and tools that can be mastered through CNC machining include lathes, grinders, and mills. CNC or computer numerical control allows extremely specific control over the positioning, speed, blending, feed rate and other precision aspects of the manufacturing process for a particular…

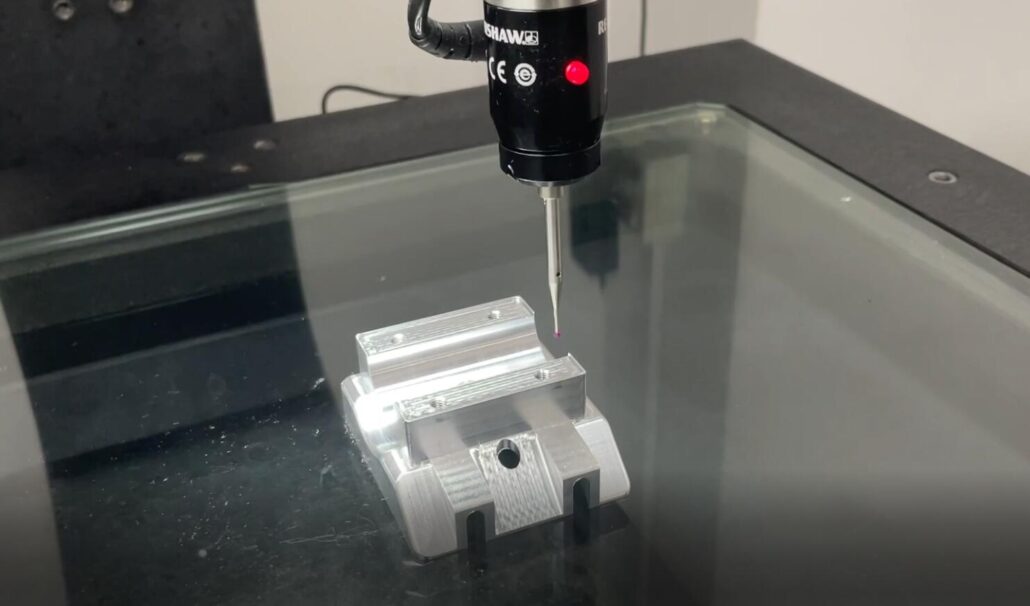

The reason why CNC precision machining is called precision machining is that its processing procedures and processing requirements are very high, and the precision requirements of products are also very high, and the machining accuracy of precision parts includes: position accuracy, dimensional accuracy, style accuracy, etc., The components that affect the precision of precision parts are…

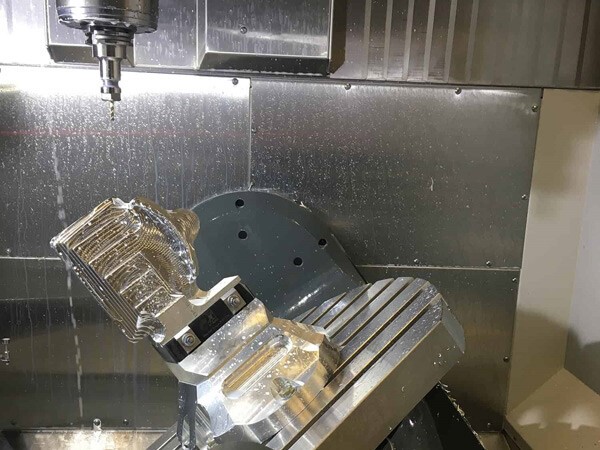

In the process of processing, every process is very critical. If there is a process that is not operated in time due to carelessness in the process of processing, it is very likely to immediately endanger the final actual effect of the product. Therefore, in the process of work, the operating staff must be very…

During the machining and cutting process, the CNC lathe is subjected to the action of the cutting force, and the elastic deformation occurs in the direction of the force, which is what we often call the phenomenon of letting the knife. Corresponding measures should be taken on the tool to deal with such deformation. The…

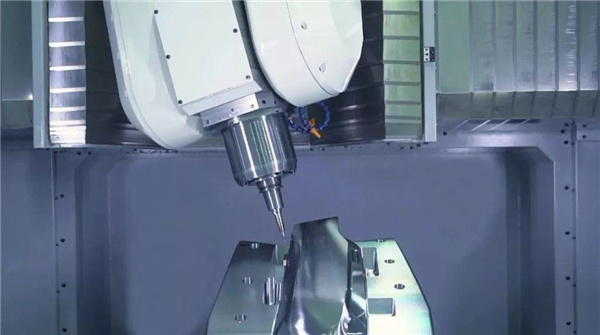

Five-axis machining is not a new term at present, and it has been widely used in enterprise practice. The following is a brief introduction to the reasons why the five-axis machining center is so popular. First, the economy of the five-axis machining center. 1: The five-axis machining center can clamp multiple workpieces at one time,…

Many people are not clear about the CNC machining process, so the CNC processing factory will briefly introduce what the CNC machining process is. The composition of the entire CNC process includes product analysis-graphic planning-process planning-pathway generation-pathway simulation-pathway output-processing-inspection. 1. Product analysis should obtain certain composition information and some specific processing requirements. 2. Graphic planning…

English

English Deutsch

Deutsch Français

Français 日本語

日本語