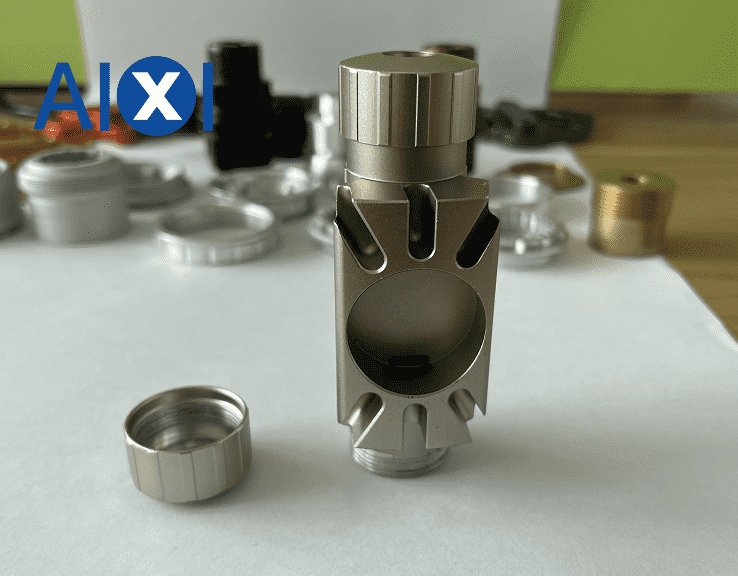

CNC machining is a method of machining using computer-controlled CNC machine tools. It generates instructions through pre-written processing programs to control the machine tool to cut along the specified path, thereby realizing the processing of the workpiece. CNC machining can be performed on almost any material from expanded polyurethane foam to nickel superalloys. CNC machining…

Archivos de Categoría: Mecanizado CNC

El mecanizado de cobre CNC es uno de los servicios de mecanizado de metales más precisos para la fabricación de piezas de cobre en todas las industrias. El cobre tiene ductilidad, alta conductividad térmica y eléctrica, resistencia a la corrosión y al desgaste, buena formabilidad durante el trabajo en caliente y en frío, y es…

Acrylic and polycarbonate are very similar in many ways, but there are some important differences. So we often choose the best material based on factors such as lead time and cost, ease of processing, and the specific application for which the material is suitable. Characteristics of Acrylic and Polycarbonate characteristic acrylic acid polycarbonate Strength and…

As AIXI Hardware, We have moved from Shenzhen to the great manufacturing city of Dongguan in September. Due to the high rent in Shenzhen, we always reduce our profits to provide customers with better prices, which is limited by our development. Therefore, after a long internal discussion, we decided to move the factory to Dongguan….

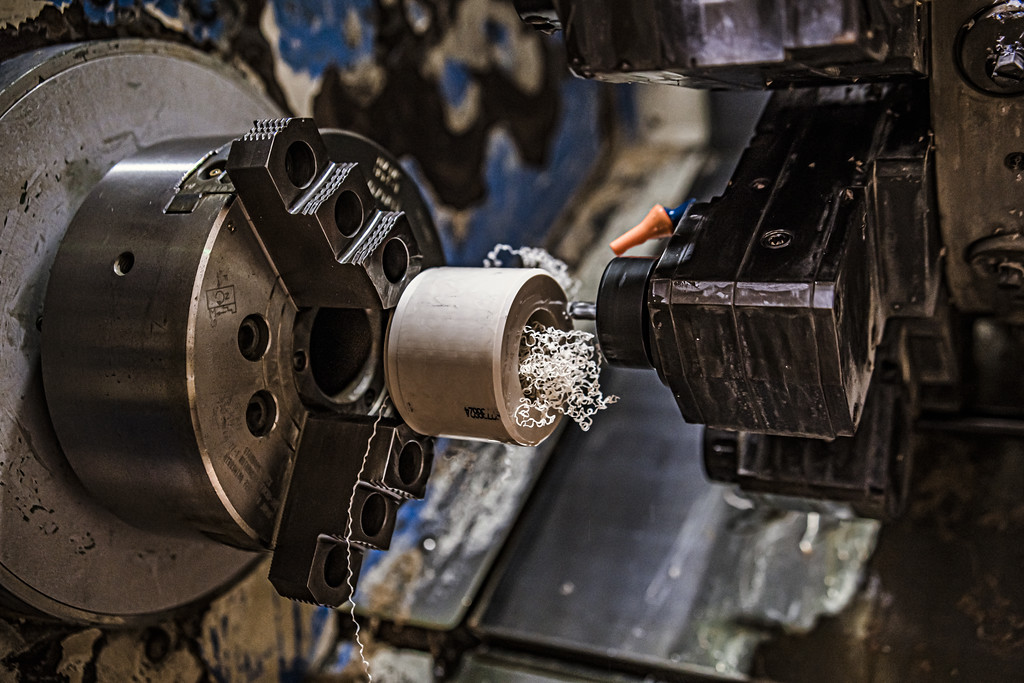

Five-axis machining CNC center CNC machine tool is a high-speed, high-efficiency, and cost-effective production equipment. It is easy to operate, has a simple process, and greatly reduces labor waste. However, sometimes failures such as unstable processing accuracy may occur under internal or external conditions. The reasons for the unstable processing accuracy of CNC machine…

Precision-manufactured CNC machining technology The application of CNC technology has brought about qualitative changes in traditional manufacturing. In recent years, the development of microelectronics technology and computer technology has given CNC technology new vitality. CNC technology and CNC equipment are an important foundation for the industrial modernization of various countries. CNC machine tools are…

G-code is the most widely used computer numerical control programming language. It is primarily used in computer-aided manufacturing to control automated machine tools and has many variants. G-code instructions are given to the machine controller (industrial computer), which tells the motor where to move, how fast to move, and what path to follow. The two…

Top Aluminum – Cost-effective Processing of Aluminum Parts If you are looking for a high-quality, high-precision, and fast aluminum CNC machining product manufacturer. You can trust Ashe to be your best choice. We have several high-end five-axis linkage CNC machine tools (a machine tool with high technological content, high precision, and dedicated to processing complex…

The Importance of Machining Tolerances in the Manufacturing Industry Tolerance matching in mechanical manufacturing is a rigorous and complex work, which requires the full attention of mechanical designers and manufacturers. In today’s society, people’s requirements for quality are extremely high. Therefore, in the process of any product manufacturing process, the standard processing tolerance is an…

What are CNC? How does it work? CNC is an acronym for Computer Numerical Control. It is a pre-programmed computer software that directs the operation of factory equipment and machinery. Use subtraction to remove unnecessary parts from a large block of material. Before the advent of CNC machines, the industry operated using manually controlled handwheels…

English

English Deutsch

Deutsch Français

Français 日本語

日本語