It is of great significance to correctly understand the connotation of the surface quality of parts, analyze various technological factors that affect the quality of the processed surface during the machining process, and improve the surface quality and product performance. The surface quality of mechanical processing refers to the micro unevenness of the processed surface…

Archivos de Categoría: Mecanizado CNC

1. Poor surface finish of the workpiece The cause of this phenomenon is mostly the damage of the tool tip and the lack of sharpness; the instability of the machine tool or the occurrence of resonance and crawling; the imperfect processing technology. You can change or sharpen the tool, and re-cut the tool; adjust the…

In order to ensure the correctness of the CNC machining process, it is a very important link to verify the processing procedure before CNC machining. At present, the development of computer simulation technology makes the technology to verify the CNC machining process in the computer environment widely used in actual production. The simulation method can…

Metallic materials refer to the general name of metallic elements or materials with metallic characteristics mainly composed of metallic elements. Including pure metals, alloys, metal materials, intermetallic compounds and special metal materials. (Note: Metal oxides (such as alumina) are not metal materials) 1. Meaning The development of human civilization and the progress of…

Fine parts processed from stainless steel have the advantages of corrosion resistance, long service life, and good mechanical and dimensional stability. Austenitic stainless steel fine parts have been widely used in medical, instrumentation and other fine machinery fields, but austenitic stainless steel data It has high strength, high plasticity and poor cutting performance, which is…

The cnc four-axis machining center was first used in the processing of curved surfaces, that is, the processing of blades. Nowadays, the cnc four-axis machining center can be applied to the processing of polyhedral parts, spiral lines (cylindrical surface oil grooves) with spiral angles, spiral grooves, cylindrical cams, cycloid, etc., which are widely used. From…

1. Is a CNC machining center or an engraving and milling machine good? CNC machining center and engraving and milling machine are more commonly used mechanical equipment, the two also have similarities and differences, if it is hard to say whether the CNC machining center is good or engraving and milling is difficult to have…

At present, CNC high-gloss machining processes (milling, turning) are not well known to technicians in most industrial industries. Practice shows that they are only really controlled by a few consumer companies. The main reason is that the previous demand is not very strong, of course, this is also closely related to cognition. Today we are…

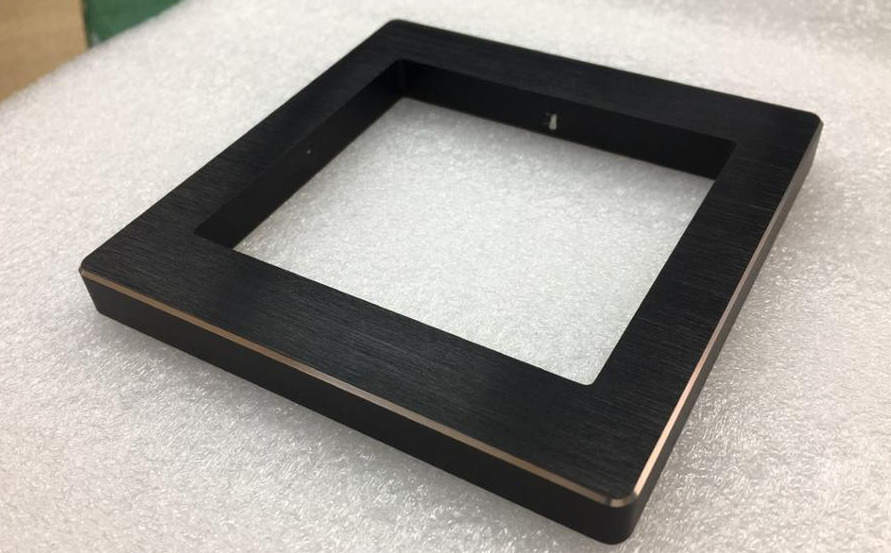

With the development of science and technology, people have put forward various new requests for the appearance and appearance of CNC processing of aluminum alloy shells. For example, when electroplating is used on a large area of CNC processed products of aluminum alloy shells, people are more and more tired of the shiny plating luster….

In cnc processing, whether it is manual programming or automatic programming, before programming, it is necessary to perform process analysis on the processed parts, formulate a processing plan, select the appropriate tool, and determine the cutting amount. In programming, some technical issues (such as tool setting points, processing routes, etc.) also need to be dealt…

English

English Deutsch

Deutsch Français

Français 日本語

日本語