El debate sobre el acero aleado frente al acero inoxidable ha estado en curso durante años. Algunas personas consideran que el acero aleado es un supertipo de acero. Por otro lado, muchos fabricantes convencen a sus clientes de utilizar acero inoxidable. Ambos tipos de acero tienen sus ventajas únicas. Esas ventajas hacen que su…

Archivos de Categoría: Material metálico

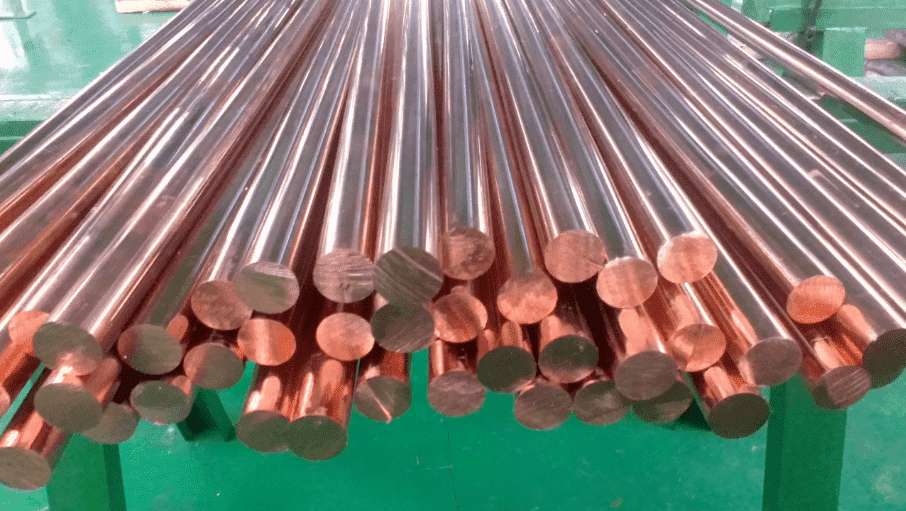

El cobre es un material muy utilizado debido a su maleabilidad y ductilidad. Sin embargo, su alto punto de fusión también contribuye a su popularidad. Por ello, los fabricantes lo utilizan para fabricar productos que resistan altas temperaturas. Todo el mundo sabe que es resistente, fuerte y rígido para fundirse. Sin embargo, menos gente conoce…

Is Aluminum A Common Prototyping Material? If you’re a product designer, you’re probably wondering, «Is aluminum a common prototyping material?» If so, you’re not alone! Aluminum is often used for prototype manufacturing due to its outstanding qualities, including corrosion resistance and strength. This makes it a highly suitable choice for various projects, from pre-production prototypes…

45 steel 45 steel is the name in GB, also called «oil steel», this steel has higher strength and better machinability. Material advantages: It has high strength and good machinability. After proper heat treatment, a certain degree of toughness, plasticity and wear resistance can be obtained. The material source is convenient. It is suitable for…

Latón El latón es una aleación de cobre y zinc, y el latón compuesto de cobre y zinc se denomina latón común. Ventajas del material: Tiene alta resistencia, alta dureza y fuerte resistencia química. Las propiedades mecánicas de corte también son excepcionales. El latón tiene una fuerte resistencia al desgaste. El latón especial también se…

Pure copper (also known as red copper) is a ductile metal with excellent electrical conductivity. The surface is rose red. It is not pure copper, it contains 99.9% copper, and some other elements are added to improve the surface and performance. Material advantages: It has good electrical conductivity, thermal conductivity, ductility, deep drawing and corrosion…

7075 aluminum alloy 7075 aluminum alloy is a cold-treated forging alloy with high strength, far better than mild steel. 7075 is one of the most powerful alloys commercially available. Material advantages: General corrosion resistance, good mechanical properties and anode reaction. The finer grains make the deep drilling performance better, the tool wear resistance is enhanced,…

6061 aluminum alloy is a high-quality aluminum alloy product produced by heat treatment and pre-stretching process. Although its strength can not be compared with 2XXX series or 7XXX series, its magnesium and silicon alloy characteristics are many. Material advantages: It has excellent processing performance, excellent welding characteristics and electroplating, good corrosion resistance, high toughness and…

45# steel, belongs to high-quality carbon structural steel Uses: Commonly used as materials for shaft parts. Mechanical properties: good mechanical processing performance and strength hardness, quenching and tempering treatment, quenching temperature 820°~850°, return water temperature 600°~650°, HRC40°. High-speed SKH-9 (commonly known as wind steel), similar to the mainland brand W6CrM05V2 Uses: It is often used…

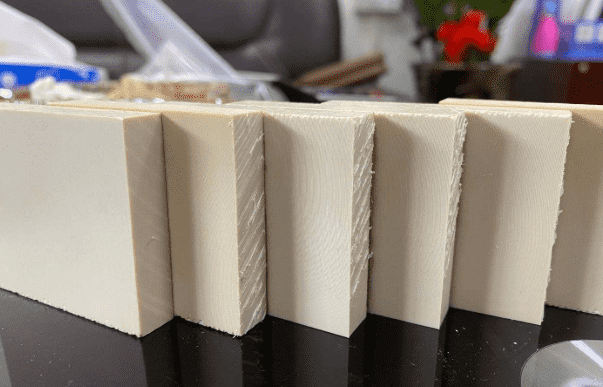

Characteristic: ①General performance: PPS is a white, high crystallinity, hard and brittle polymer. The relative density of pure PPS is 1.3, but it will increase after modification. PPS has a very small water absorption rate, generally only about 0.03%. PPS has good flame retardancy, and its oxygen index is as high as 44%. Compared with…

- 1

- 2

English

English Deutsch

Deutsch Français

Français 日本語

日本語