Key points: Analyze the product (specific material bai performance, appearance requirements, whether du undercut, whether there is a special process, whether the zhi type is defective) Difficulties: Improve mold life, control costs (the easiest to process), and have a comprehensive grasp of the best appearance of the product. Simply put, it is the design. The…

Archivos de Categoría: Herramientas de inyección

Tolerance table of injection plastic parts (according to SJ1372 standard) size mm Accuracy class 1 2 3 4 5 6 7 8 Tolerance mm ~3 0.04 0.06 0.08 0.12 0.16 0.22 0.32 0.48 >3 ~ 6 0.05 0.07 0.08 0.14 0.18 0.28 0.35 0.56 >6 ~ 10 0.06 0.08 0.10 0.16 0.20 0.32 0.40 0.61…

Mold temperature: The mold temperature has a great influence on the intrinsic performance and apparent quality of the product. The temperature of the mold depends on the crystallinity of the plastic, the size and structure of the product, performance requirements, and other process conditions (melt temperature, injection speed and injection pressure, molding cycle, etc.). Pressure…

The large-scale casting machine tool workbench is an important point of development in our country at present, and it is also one of the standard lines to measure the level of China’s foundry industry. The large-scale casting machine tool workbench is to melt metal into a liquid that meets certain requirements and pour it into…

Compared with other molds, injection molds have a more complex and precise structure, and have higher requirements for operation and maintenance of products. Therefore, in the entire production process, the use of positive solutions and careful maintenance and maintenance are very important to maintain the normal production of the enterprise and improve the efficiency of…

By using the right combination of equipment and software, the efficiency is significantly improved. The automation system has the obvious advantage of increasing productivity, as much as two-thirds in some applications, while providing a more precise method to maintain inventory during this process In the meantime, they improve operational efficiency and productivity, reduce inventory levels,…

The design of injection molded parts generally requires the design of the number and arrangement of mold cavities. The cavity of the mold cannot simply apply the dimensional tolerance of the mechanical parts. The dimensional accuracy of the plastic parts will be affected by many factors such as the structure of the plastic parts, the…

Whether a set of injection molds are successfully opened depends mainly on whether the injection molds have a lot of problems? A successful set of molds can be reflected in product appearance, assembly, and production efficiency. Then, relatively speaking, the more injection mold molding problems, the greater the possibility that the mold is not opened…

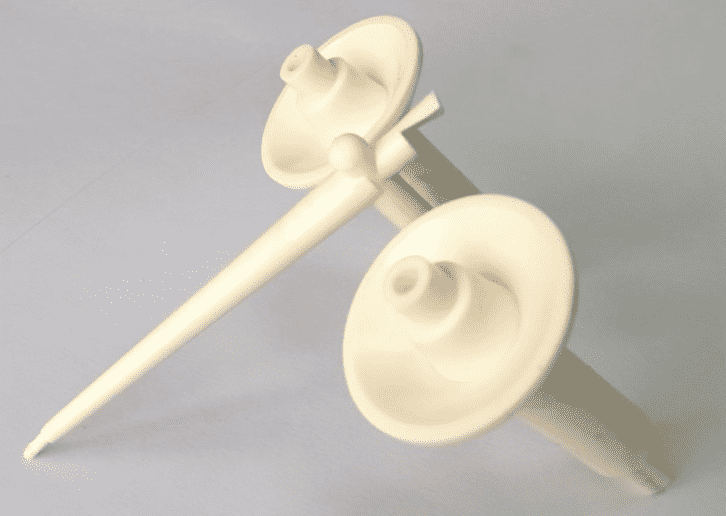

As an injection mold technician, do you know these 18 knowledges? 01 Shot Tsui The melt usually flows from the nozzle into the nozzle, but in some molds, the nozzle is part of the mold because it extends to the bottom of the mold. There are also two main types of nozzles: open type nozzles…

In the injection molding process, it will often be difficult to solve the shrinkage of a certain part of the product. In this case, only the back pressure can be solved by appropriately adjusting the back pressure parameters. The reason for using back pressure is that when the screw rotates, the heated plasticized plastic is…

- 1

- 2

English

English Deutsch

Deutsch Français

Français 日本語

日本語