1 Carbon structural steel: Q195-Q195F, Q195b, Q195, Q215-Q215AF, Q215Ab, Q215A, Q215BF, Q215Bb, Q215B, Q235-Q235AF, Q235Ab, Q235A, Q235BF, Q235Bb, Q235B, Q235C, Q235D, Q255-Q255A, Q255B, Q275-Q275 2 Low alloy high strength structural steel: Composition of general low alloy high strength structural steel grades Q295-Q295A, Q295B, Q345-Q345A, Q345B, Q345C, Q345D, Q345E, Q390-Q390A, Q390B, Q390C, Q390D, Q390E, Q420-Q420A, Q420B,…

Archivos de Categoría: Conocimiento de los materiales

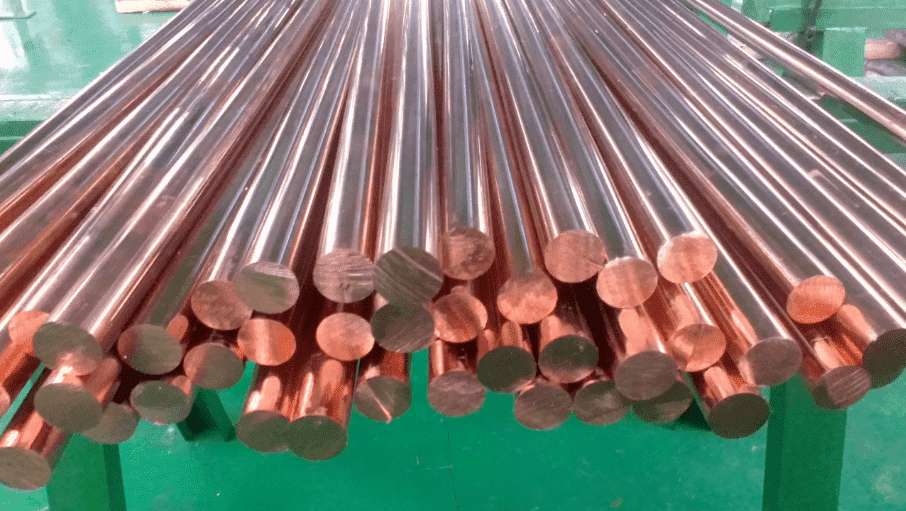

Chinese copper processing materials can be divided into: ordinary copper (T1, T2, T3, T4), oxygen-free copper (TU1, TU2 and high-purity, vacuum oxygen-free copper), deoxidized copper (TUP, TUMn), adding a small amount of alloy Elements of special copper (copper arsenic, tellurium copper, silver copper) four categories. The electrical conductivity and thermal conductivity of red copper is…

Bronze has the characteristics of low melting point, high hardness, strong plasticity, wear resistance, corrosion resistance, bright color, etc. It is suitable for casting various appliances, mechanical parts, bearings, gears, etc. Bronze categories include food, wine, water, musical instruments, weapons, carts, agricultural implements and tools, currency, seals and symbols, weights and measures, bronze mirrors, and…

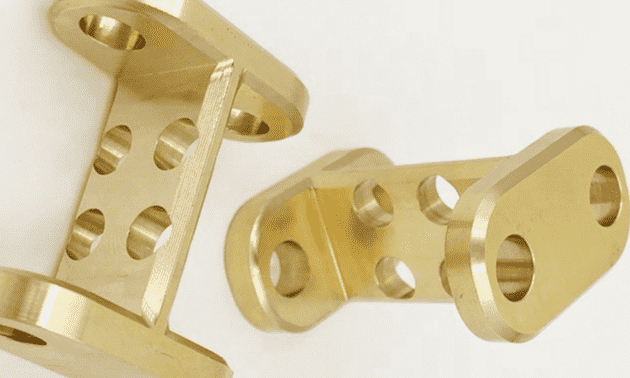

El latón ordinario es una aleación binaria de cobre-zinc: H90, H80, H68, H62 El latón especial se obtiene añadiendo otros elementos de aleación a la aleación binaria de cobre-zinc: latón al plomo, latón al manganeso, latón al silicio, latón al níquel, latón al aluminio, latón al estaño, latón al hierro, cobre amarillo al bismuto, latón…

Aluminum alloy materials are the most widely used non-ferrous metal structural parts in the industrial field, and are widely used in aviation, aerospace, automotive, machinery manufacturing, shipping, electronic machining, molds and chemical industries. Aluminum alloy materials are divided into different grades. Each grade material contains slightly different elements. Different grades are suitable for different ranges:…

The particularity of the wire processing industry makes the requirements of the copper plating process different from the conventional copper plating of steel parts. Therefore, how to choose a copper plating process suitable for wire processing is a very important subject. Generally, the basis for selecting the plating process is first of all the requirements…

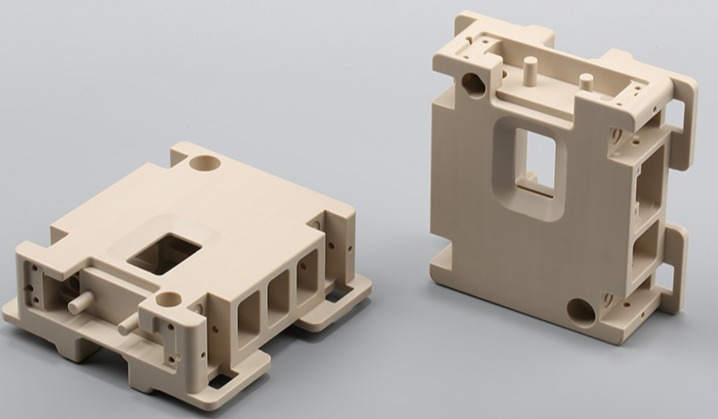

Poly-ether-ether-ketone (PEEK) is a thermoplastic special engineering plastic with excellent performance in abrasion resistance, temperature resistance, corrosion resistance, etc., which can meet various complex Material requirements of parts and components under working conditions and harsh environments. In recent years, with the introduction of domestic PEEK raw materials, the price of raw materials has been reduced,…

1. Introduction Since the beginning of the 1990s, the application trend of major metal materials in the world has changed significantly. The application of traditional materials such as steel, copper, lead and zinc has grown slowly, while the light metal materials represented by magnesium alloy have sprung up. The rate of 20% per year continues…

Commonly used hardware mainly includes stainless steel, cast iron, carbon steel, aluminum plate, copper rod, etc. There are many brands. Stainless steel sus304, sus316, sus430; Aluminum plate has 5052, 6061, hard aluminum lY12, rust-proof aluminum lF5, etc. Carbon steel domestic brands Q235, 08F, and 1018, 1012 and other brands, Cast iron HT150, HT200, etc.; Brass…

Acabado de superficies, BLOG, Conocimiento de los materiales, Conocimientos de soldadura, Corte de alambre, Corte por láser, Creación rápida de prototipos, Die Casting, Fundición al vacío, Herramientas de inyección, Impresión 3D de metales, Industria automotriz, Industria de auriculares, Industria del audio, Material de plastico, Material metálico, Mecanizado CNC, Mecanizado de torneado y fresado, Piezas de sujeción, Plástico de impresión 3D, Procesamiento de engranajes, Seguro de calidad, Servicios de chapa metálica, Servicios de estampado, Servicios de extrusión, Sin categorizar, Termoformado, Tubo/tubo curvado

Talk the surface treatment

1: anodizing In order to enrich the color of the product, we can usually make some oxidation treatment. The oxidation treatment can make all the colors except white. The oxidation treatment is done for the aluminum alloy. If it is other materials, it can’t make anodization. Steel material, you can choose plating, etc. anodized aluminum,…

English

English Deutsch

Deutsch Français

Français 日本語

日本語