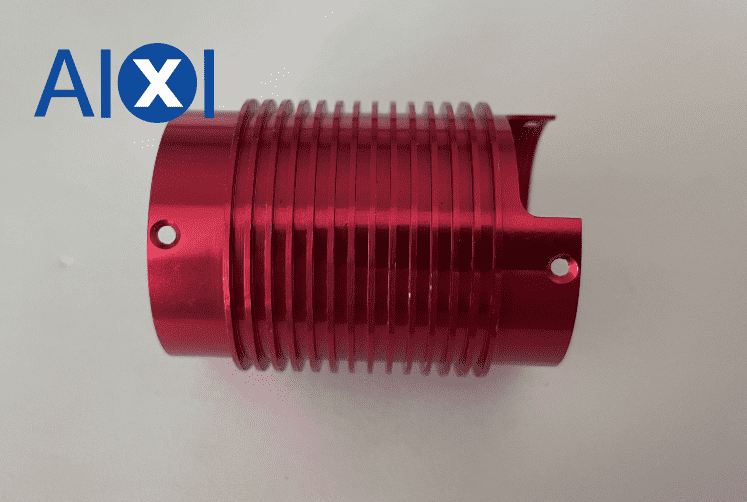

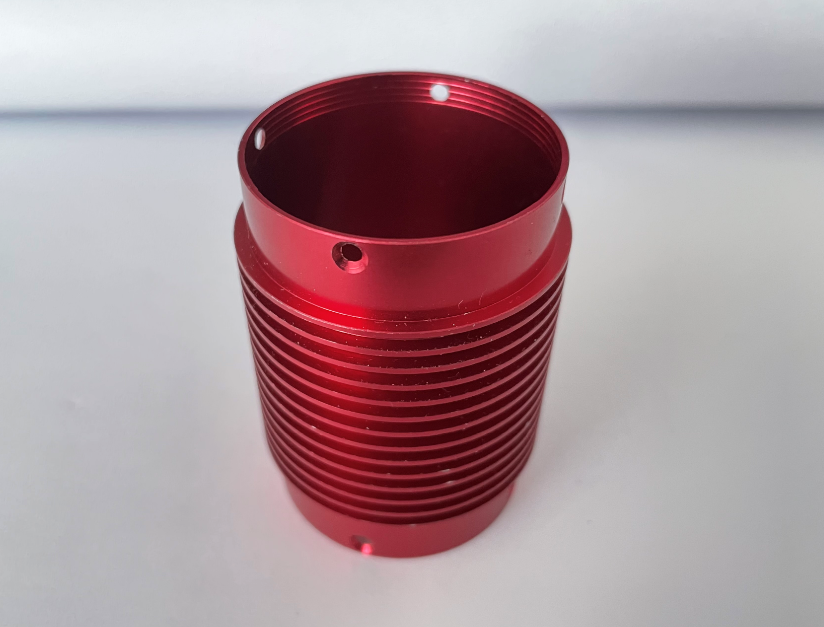

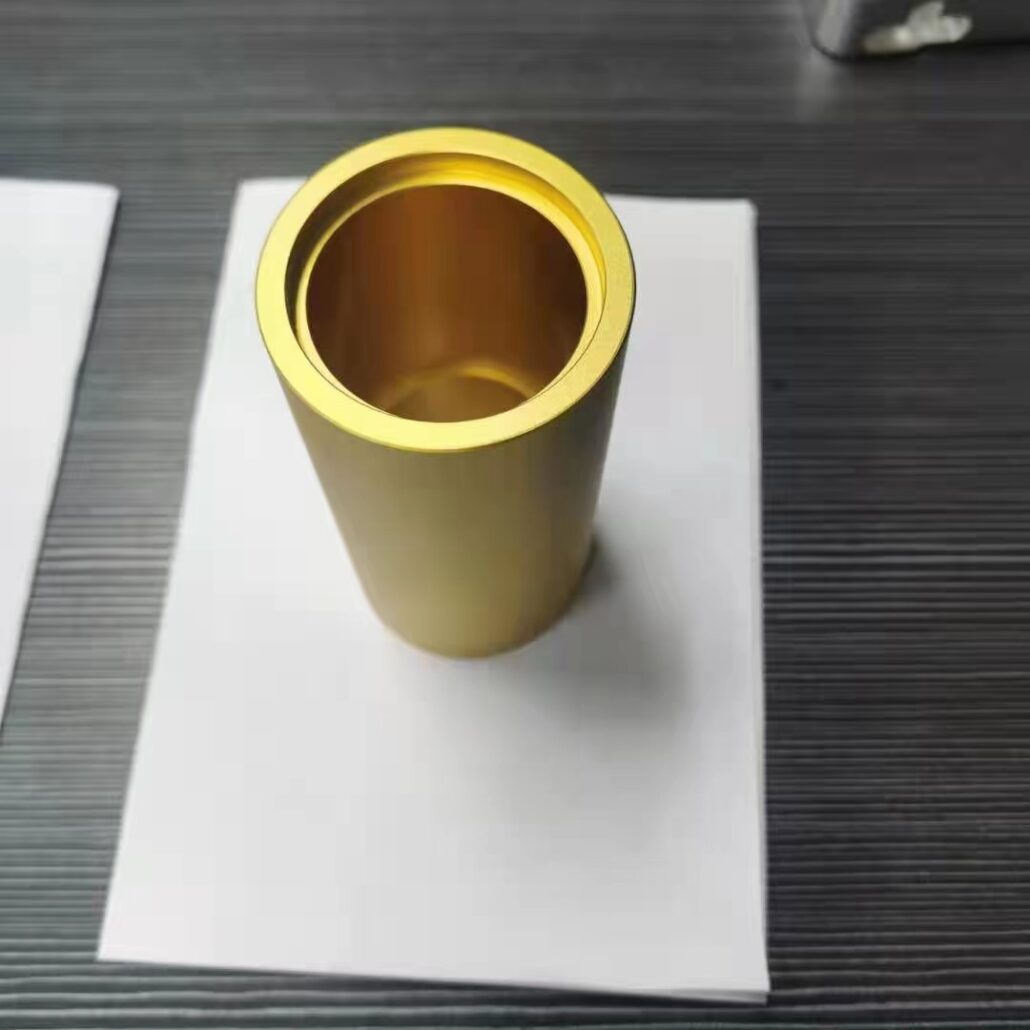

1 Appearance The appearance of the coating is consistent in color and lustre, and the crystals are fine; the coating has no blistering, peeling, pinholes, and burning; no obvious roughness and burrs; no obvious water marks and fingerprints. 2 Plating thickness The thickness of the coating on the main surface meets the requirements of the…

Archivos de Categoría: Acabado de superficies

Aluminum oxidation treatment is a processing technology that many aluminum products will choose. It can make the aluminum surface obtain a high-quality protective film and have certain decorative properties. What are the characteristics of aluminum anodized film? 1. High strength The strength of pure aluminum anodic oxide film is higher than that of aluminum alloy…

With the help of oxidation treatment, metal materials can be given a bright appearance, excellent corrosion resistance, wear resistance, insulation and other characteristics, and then achieve various design requirements. At this stage, the most common application is the oxidation treatment of aluminum alloys. Considering that the oxide film of aluminum has a fine structure, good…

Both aluminum anodizing and conductive oxidation are popular processes. Manufacturers use them to get desired properties in aluminum material. However, laymen do not understand these processes well, and many don’t know their differences. This motivated me to write a detailed article on aluminum anodizing vs conductive oxidation. This article will uncover the key differences…

Metals may seem hard, but given enough time, even pure air can dissipate them. Oxygen reacts with aluminum alloys to form rusted metal oxides, but now it turns out that metal oxides may save aluminum alloy life. Research has found that aluminum can be protected from further oxidation by a thin film of aluminum oxide,…

1. Different thickness: The thickness of hard oxide is thicker than that of ordinary oxide. Generally, the thickness of ordinary oxide film is 8–12 um, and the thickness of hard oxide film is generally 40-70 um. 2. Different hardness: Hardness: Normal oxidation is generally HV250-350, and hard oxidation is generally HV350-550. 3. the temperature is…

1. The surface is hard, and the hardness can reach about HV500; 2. The thickness of the oxide film of 25-250 microns; 3. Strong adhesion, oxidation characteristics can be generated according to hard oxidation: 50% of the oxide film formed inside the aluminum alloy with a permeability of 50% adheres to the surface of the…

Passivation is a method to transform the metal surface into a state that is not easy to be oxidized, and to delay the corrosion rate of the metal. In addition, the phenomenon that an active metal or alloy becomes a noble metal with its chemical activity greatly reduced is also called passivation. Passivation advantages 1….

With the continuous advancement of science and technology, there are more and more kinds of aluminum alloy surface treatment processes. The appearance of each treatment process is different, and its use is also different. What are the surface treatment processes of aluminum alloy 1. Highlight cutting Use a precision engraving machine to cut some parts…

Hello , if you can’t find a good color for anodized , you also can tell us the Pantone code, we can buy Pantone code color then anodized same color . More surface finsihing we can offer .

English

English Deutsch

Deutsch Français

Français 日本語

日本語