What is CNC Machined Aluminum? You may have heard about the benefits of CNC machined aluminum parts, but do you know exactly what it is? Aluminum is nonmagnetic, soft, and malleable. Yet, it has exceptional corrosion resistance and is a popular material used in many industries. Read on to learn more about this alloy. CNC…

How Thin Can You CNC Aluminum? If you’ve ever wondered how to CNC aluminum, you might have wondered whether you should use straight-flute bits or fluted end mills. While both types of cutters can cut aluminum, wood can be faster to cut. However, wood can suffer from Radial Chip Thinning if you cut it less…

Can You CNC 6061 Aluminum? There are many different alloys made from aluminum, but there is one grade that is particularly well-suited for CNC machining: 6061. This grade of aluminum is commonly called «tooling plate» and has the right properties to maintain a high level of flatness. However, 6061 is still the most popular aluminum…

El aluminio CNC es famoso por su resistencia. Su uso es un elemento básico en muchas industrias, incluidas la aeroespacial y la automotriz. Sin embargo, los compradores siguen confundidos sobre la resistencia del aluminio CNC durante el proceso de selección. Entonces, preguntan: ¿qué tan fuerte es el aluminio CNC? El aluminio CNC tiene una…

Can You CNC Aluminum? Can you CNC aluminum? Yes, you can. However, there are several things to keep in mind. Aluminum is extremely difficult to cut and requires high-quality tooling. Here are a few tips for cutting aluminum. First, don’t forget to lubricate the cutting tool. Aluminum will stick to the bit if it’s not…

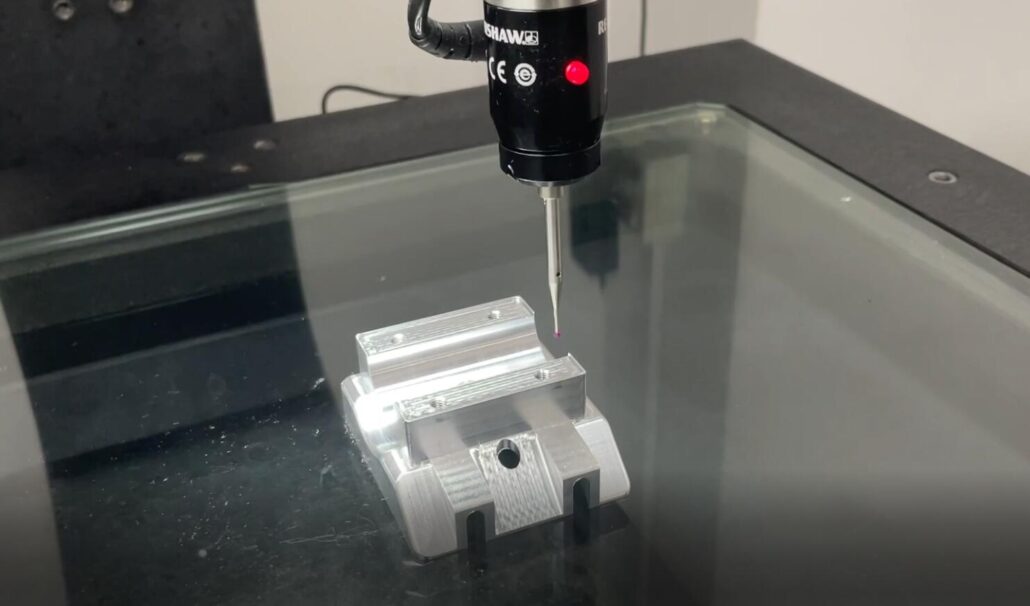

What Is CNC Prototyping? CNC aluminum prototyping is a popular method for creating prototypes. The process is mostly automated and requires little manual work, but a well-experienced user can still be an invaluable asset in creating a high-quality part. An experienced user will also be aware of the intricacies of different materials, as well as…

Is Aluminum A Common Prototyping Material? If you’re a product designer, you’re probably wondering, «Is aluminum a common prototyping material?» If so, you’re not alone! Aluminum is often used for prototype manufacturing due to its outstanding qualities, including corrosion resistance and strength. This makes it a highly suitable choice for various projects, from pre-production prototypes…

According our experience : 1: Quote speed If quantity lower 10 products , can’t quote within 8-10hours , it means can’t reply within working day , i think this is not real factory , most likely is a trade company , because they need wait other company quote , then quote to customer . so…

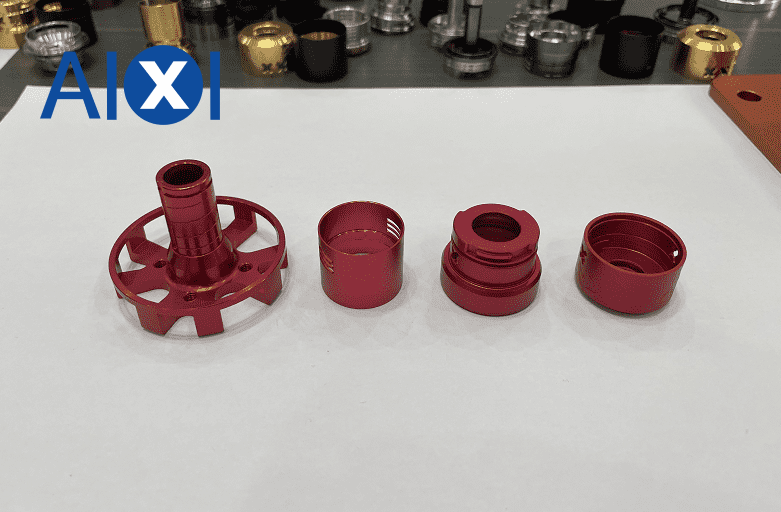

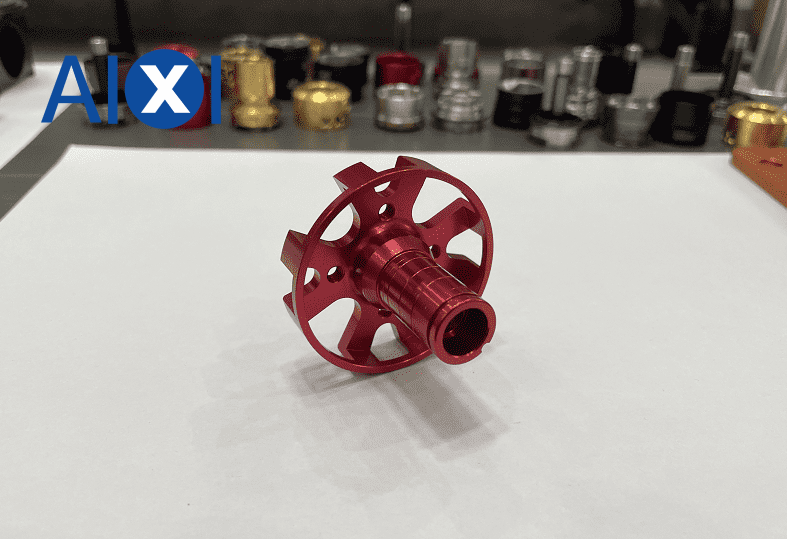

1 Appearance The appearance of the coating is consistent in color and lustre, and the crystals are fine; the coating has no blistering, peeling, pinholes, and burning; no obvious roughness and burrs; no obvious water marks and fingerprints. 2 Plating thickness The thickness of the coating on the main surface meets the requirements of the…

Aluminum oxidation treatment is a processing technology that many aluminum products will choose. It can make the aluminum surface obtain a high-quality protective film and have certain decorative properties. What are the characteristics of aluminum anodized film? 1. High strength The strength of pure aluminum anodic oxide film is higher than that of aluminum alloy…

English

English Deutsch

Deutsch Français

Français 日本語

日本語