Sheet metal parts are products processed by sheet metal technology, and daily life is inseparable from sheet metal parts. Sheet metal parts are manufactured by filament power winding, laser cutting, heavy processing, metal bonding, metal drawing, plasma cutting, precision welding, roll forming, metal sheet bending, die forging, water jet cutting, precision welding . Sheet metal…

For those who are new to sheet metal processing, the vast majority of people confuse the concepts of sheet metal processing and stamping. Although these two have many similarities, there are still certain differences. First of all, conceptually, sheet metal processing refers to the processing of metal plates, that is, the use of plates to…

Analysis of the sheet metal processing market and materials. At present, Chinese car parts companies are not only facing violent homogenization competition of multinational companies and domestic companies, but also the upstream and inferior kneading of raw materials and host country dealers. Continuously improve the quality of standardized products. And the status quo of most…

With the increasing market demand for sheet metal processing, the design speed of the demanded sheet metal parts has been further improved, so there will be some tips to help us use sheet metal processing better when it is used! 1. In order to avoid broken chips and hurt people, the baffle should be installed…

The materials commonly used in sheet metal processing are cold-rolled sheet (SPCC), hot-rolled sheet (SHCC), galvanized sheet (SECC, SGCC), copper (CU) brass, copper, beryllium copper, aluminum sheet (6061, 5052, 1010, 1060, 6063, duralumin, etc.), stainless steel (mirror surface, brushed surface, matte surface), depending on the role of the product, the choice of materials is different,…

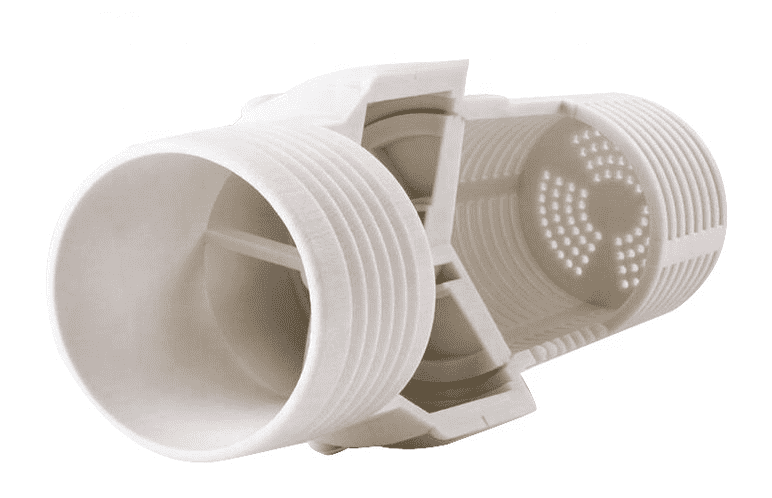

Compared with other 3D printing processes, sla3d printing has the characteristics of wide printing shape, fast forming speed, high precision, and best surface finish. The application fields include almost all industries in the manufacturing field. Has been more and more widely used. At present, it is mainly applied to the design verification of new product…

1. Unsafe factors in the machining process During the machining of magnesium alloys, the resulting chips and fine powders are in danger of burning or exploding. The chip size generated in the initial processing stage is large. Due to the high thermal conductivity of magnesium, the generated frictional heat can be quickly dissipated, so it…

3C products usually refer to computers, tablets, mobile phones, digital cameras, walkmans, electronic dictionaries, audio-visual playback hardware devices or digital audio players, etc. The so-called «3C products» are a combination of Computer, Communication, and Consumer Electronics, also known as «Information Appliances». Because the volume of 3C products is generally not large, they often add a…

CNC machining, CNC machining refers to machining using CNC machining tools. CNC index-controlled machine tools are programmed and controlled by CNC machining languages, usually G codes. The CNC machining G code language tells the CNC machine tool what kind of Cartesian position coordinates the machining tool uses, and controls the tool’s feed speed and spindle…

1. Polishing and polishing Due to its special forming method, the 3D printed model will have a stepped layer on the surface of the model. These layered patterns are inevitable even for the finest printers currently available. Although we can adjust the parameters during layering or the placement of the model to make the layer…

English

English Deutsch

Deutsch Français

Français 日本語

日本語