The particularity of the wire processing industry makes the requirements of the copper plating process different from the conventional copper plating of steel parts. Therefore, how to choose a copper plating process suitable for wire processing is a very important subject. Generally, the basis for selecting the plating process is first of all the requirements…

With the development of science and technology, people have put forward various new requests for the appearance and appearance of CNC processing of aluminum alloy shells. For example, when electroplating is used on a large area of CNC processed products of aluminum alloy shells, people are more and more tired of the shiny plating luster….

In cnc processing, whether it is manual programming or automatic programming, before programming, it is necessary to perform process analysis on the processed parts, formulate a processing plan, select the appropriate tool, and determine the cutting amount. In programming, some technical issues (such as tool setting points, processing routes, etc.) also need to be dealt…

Aluminum alloy CNC machining has great advantages over manual machining. For example, the aluminum alloy parts produced by CNC machining are very accurate and repeatable; aluminum alloy CNC machining can produce parts with complex shapes that cannot be manually processed. So how much do you know about the operating principles of aluminum alloy CNC machining?…

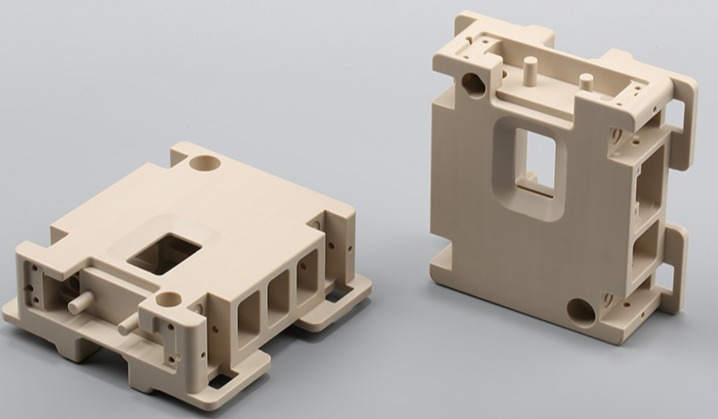

Poly-ether-ether-ketone (PEEK) is a thermoplastic special engineering plastic with excellent performance in abrasion resistance, temperature resistance, corrosion resistance, etc., which can meet various complex Material requirements of parts and components under working conditions and harsh environments. In recent years, with the introduction of domestic PEEK raw materials, the price of raw materials has been reduced,…

Now the common equipment in industrial production and processing has been favored by merchants in different fields and industries. The overall performance is very excellent. After several years of improvement and improvement, the production and processing efficiency has also been improved, and the equipment structure has been improved. Simplified, suitable for use in more fields….

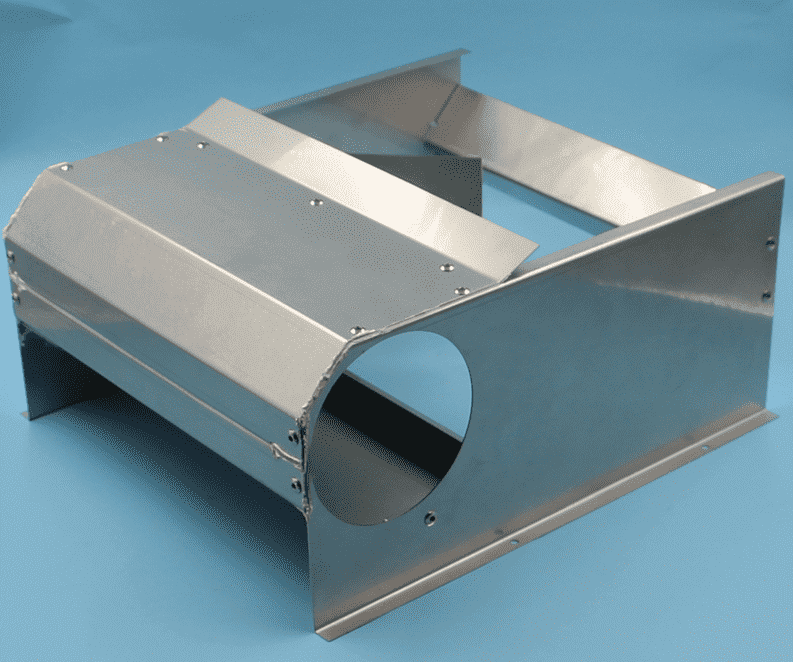

Sheet metal processing has always been an important part of the metal manufacturing industry. With the rapid development of China’s economy in recent years, China’s sheet metal processing industry is also booming. However, compared with foreign sheet metal processing models, due to the late start of sheet metal processing in China, there are still certain…

Sheet metal processing cabinets are classified into equipment cabinets and wiring cabinets by function. In the design of sheet metal cabinet processing, we must not only consider the use of sheet metal cabinets, but also adjust the space design and adjustment of sheet metal according to the equipment assembly of sheet metal cabinets. Load capacity….

In the production process of aluminum alloy castings, stomata defects often occur due to improper operation or unskilled processes. Once the blowhole appears, it will often cause the casting to be scrapped due to quality problems and increase production costs. However, there are many reasons for the blowhole defects in aluminum alloy castings. Many companies…

Aluminum casting is divided into aluminum alloy casting and high-pressure casting in general. It is often said that die casting refers to high-pressure die casting, which uses a die-casting machine to compact the molten aluminum alloy profile in a high-speed mold and rapidly cool it under high pressure. And usually casting is divided into sand…

English

English Deutsch

Deutsch Français

Français 日本語

日本語