In recent years, PP fiber reinforced materials have developed rapidly in the modified plastics industry, and most of the glass fiber reinforced materials used in the automotive field are PP substrates. With the improvement of plastic modification technology and the needs of the development of the automotive industry, the development trend of long glass fiber…

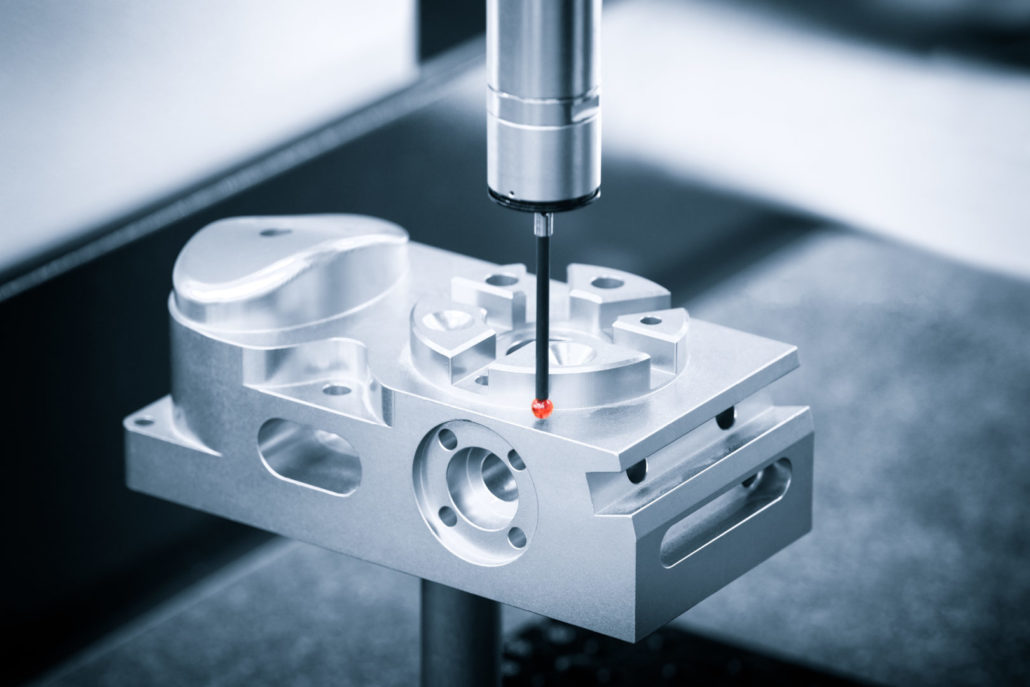

The CNC machining center can process various complex workpieces by executing the processing program. There are two sources for processing programs: manual programming and programming software. For simple processing tasks, such as milling straight grooves, steps, drilling, etc., it can be completed by manual programming, which is simple, direct and efficient; but for complex three-dimensional…

What is the difference between 3-axis, 4-axis, and 5-axis in CNC machining? What are their advantages? Which products are they suitable for processing? Three-axis CNC machining: generally refers to three axes that move linearly in different directions, such as up and down, front and back, left and right. Three axes can only process one…

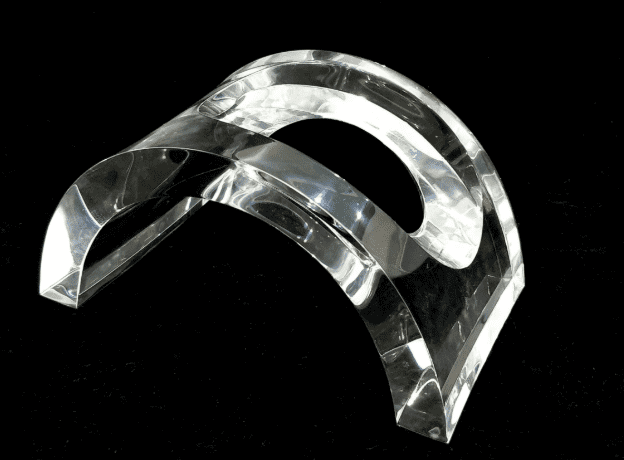

The common acrylic bending in life is basically a thinner plate to be bent after heating, and local bending can be directly heated on the bending machine and then bend; then what if it is a thicker plate? What to do? Let AIXI Hardware explain to you: The overall bending process of 18MM thick acrylic…

CNC spark machine (EDM) is a computer digitally controlled spark machine to realize multi-axis linkage processing equipment. The CNC spark machine (EDM) realizes automatic control through the computer to complete complex and precise spark machining. In the actual machining process, the computer sends instructions to control the EDM according to the input program to realize…

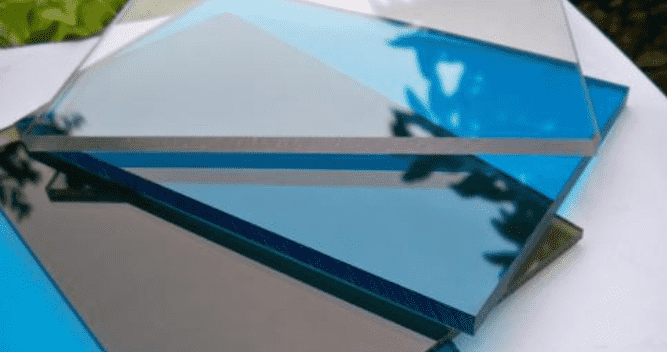

(Polycarbonate) Specific gravity: 1.18-1.20 g/cm3 Molding shrinkage: 0.5-0.8% Molding temperature: 230-320℃ Drying conditions: 110-120℃ 8 hours Material performance High impact strength, good dimensional stability, colorless and transparent, good colorability, electrical insulation, corrosion resistance, wear resistance, but poor self-lubricity, stress cracking tendency, easy to hydrolyze at high temperature, poor compatibility with other resins . Suitable for…

(Polyamide) Specific gravity A6-1.14g/cm3 PA66-1.15g/cm3 PA1010-1.05g/cm3 Molding shrinkage rate A6-0.8-2.5% PA66-1.5-2.2% Molding temperature: 220-300℃ Drying conditions: 100-110℃ for 12 hours Material performance Tough, abrasion-resistant, oil-resistant, water-resistant, anti-enzyme bacteria, but high water absorption. Nylon 6 has good elasticity, high impact strength, and greater water absorption. Nylon 66 has better performance than nylon 6, high strength and…

(Polyethylene) Specific gravity: 0.94-0.96 g/cm3 Mold shrinkage: 1.5-3.6% Molding temperature: 140-220℃ Material performance Corrosion resistance, excellent electrical insulation (especially high-frequency insulation), can be chlorinated, modified by irradiation, and can be reinforced with glass fiber. Low pressure polyethylene has a melting point, rigidity, hardness and strength, low water absorption, and good The electrical properties and radiation…

(Polypropylene) Specific gravity: 0.9-0.91 g/cm3 Mold shrinkage: 1.0-2.5% Molding temperature: 160-220℃ Material performance Low density, strength and rigidity, hardness and heat resistance are better than low-pressure polyethylene, and can be used at about 100 degrees. It has good electrical properties and high-frequency insulation. It is not affected by humidity, but it becomes brittle at low…

(Polyoxymethylene) Specific gravity: 1.41-1.43 g/cm3 Mold shrinkage: 1.2-3.0% Molding temperature: 170-200℃ Drying conditions: 80-90℃ 2 hours Material performance It has good overall performance, high strength and rigidity, good wear resistance, low water absorption, good dimensional stability, but poor thermal stability, easy to burn, and easy to age when exposed to the atmosphere. Suitable for making…

English

English Deutsch

Deutsch Français

Français 日本語

日本語