Can You CNC Aluminum?

Can you CNC aluminum? Yes, you can. However, there are several things to keep in mind. Aluminum is extremely difficult to cut and requires high-quality tooling. Here are a few tips for cutting aluminum. First, don’t forget to lubricate the cutting tool. Aluminum will stick to the bit if it’s not lubricated. If you use oil mist while cutting, it will help keep the cutting process smoother.

If you have a CNC router, you should know that aluminum is quite different from plastics, so you need to make sure you use the right type of cutter for this material. Plastics often need down-cutting tools, but aluminum is much harder and requires cutters with a solid angle. A straight-flute bit will have a walloping effect while cutting aluminum, so if you want a smooth shear, try using a solid angle cutter.

The cut depth of aluminum is determined by its grade. It is easiest to cut aluminum that is thinner than the rest of the material. However, deeper cuts are more difficult to remove, and the process will take several passes. If you are machining aluminum, make sure that the feed rate is low enough to avoid breaking the bit. In addition, make sure to use compressed air during the cutting process to keep the cutting bit cool. Remember that if you don’t optimize the CNC aluminum cut, you could wreck the machine!

Aluminum has high flexural strength, so you need to ensure that your machine is rigid enough to handle the material. Compared to wood or plastic, aluminum requires more rigidity than the latter. You don’t want to force your machine to flex because the material is too soft. If this is the case, use stubby endmills to give yourself more leverage. And, as a last, remember to lubricate the material well.

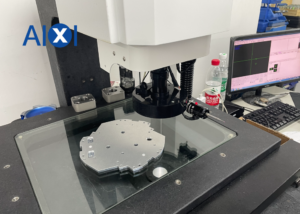

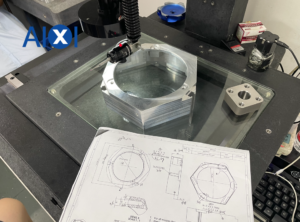

If you are looking for a way to reduce manufacturing costs, you should consider CNC aluminum parts. CNC aluminum machining reduces costs by improving speed, accuracy, and efficiency of production. Superior Joining uses state-of-the-art machine tools and software to help you design and manufacture the parts you need. The company uses high-precision CNC aluminum machining to meet deadlines, and we can produce custom CNC aluminum parts to fit your specifications.

Depending on your specific needs, CNC aluminum parts may be fabricated from various metals, including ABS. ABS is a material that is common for 3D printing and is a lightweight material that offers above-average impact strength. Other machinable plastics include PC, ABS+PC, PP, and HDPE. CNC aluminum parts can also be combined with other manufacturing processes to improve functionality and performance. To reduce costs and increase speed, CNC machining can be used for the manufacturing of a variety of aluminum components.

Using CNC aluminum parts requires advanced knowledge of machining processes. Experienced CNC operators should be able to create accurate parts without any problem. The machines are highly accurate and efficient, and CNC aluminum parts are made of the highest quality.

English

English Deutsch

Deutsch Français

Français 日本語

日本語