What Are the Benefits of Anodizing Aluminum?

What are the benefits of anodizing aluminium? Anodizing aluminum improves the hardness of the material and reduces friction. Anodising aluminum is an environmentally friendly option compared to electroplating, spraying or etching. Anodizing aluminium is also more reflective than etched aluminum. It is used to coat the exterior of aircrafts, ships, and other vehicles.

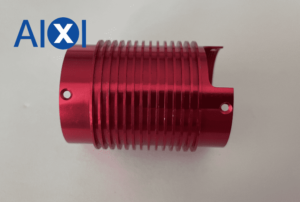

Anodizing aluminum provides greater hardness, corrosion resistance and lower friction

There are many different types of anodizing for aluminum. Some of these materials have been anodized with chromic acid or sulfuric acid. Then, certain parts are dyed or hard anodized. In general, hard anodizing is more expensive and takes more time. Other materials have a different purpose. The following are just a few examples.

Type III anodize provides greater hardness, corrosion resistance and lower slip. The aluminum oxide surface is equivalent to that of case-hardened steel. Hard anodized aluminum is extremely stable and can withstand immersion up to five years. Additionally, it offers reduced coefficient of friction and allows for neutral mate with dissimilar metals. For these reasons, many different industries are choosing anodized aluminum as a material for their products.

The process of anodizing aluminum creates an oxide film that is more durable than raw aluminum. It is an integrated layer with the aluminum substrate, not an external coating. The resulting film is more resistant to rust, peeling, and flaking. Unlike electroplating, anodizing is environmentally friendly. The aluminum oxide layer imparts corrosion resistance and weather resistance to metals.

Anodizing aluminum has multiple advantages. While unsealed hard anodizing is more durable and less susceptible to corrosive environments, unsealed hard anodising is a better choice for most applications. Hard anodized aluminum also exhibits superior wear resistance. Anodizing aluminum reduces environmental and economic losses caused by friction. The friction reduction benefits can be felt in a variety of applications.

It is more environmentally friendly than electroplating

In addition to being more durable and long-lasting, anodized aluminum is also more environmentally friendly than electroplating. The process uses aluminum alloy rather than electroplating, and it does not use heavy metals that are subject to the RCRA or VOCs. The result is a finish that provides improved wear protection and reduced friction. Powder coating, meanwhile, does not use solvents and is much more cost-effective.

Anodizing aluminum is a process that converts aluminum’s surface into an oxide layer by passing electrical current through an acid electrolyte bath. It is a highly controlled process that achieves the specifications necessary for the end product. Because aluminum oxide is extremely hard, the resulting finish is resistant to corrosion, wear, and discoloration. In addition to a hard finish, anodized aluminum improves adhesion, surface lubricity, and aesthetics.

The process uses novel electrolytes to achieve promising results in aluminum electroplating. An ionic liquid formulation is a good compromise between basic properties required to replace cadmium while preventing the addition of non-environmentally friendly, toxic, and hazardous additives. These ingredients are also more expensive than standard electroplating. This is because the coating process involves a chemical reaction that can cause corrosion.

Compared to other methods of sacrificial coating, anodizing aluminum is less toxic. It is also more environmentally friendly. Aluminum coatings can be applied to ferrous alloy steel with minimal waste. In addition to being more durable, anodized aluminum is safer to handle. In addition, aluminum can be used on aeronautical components made of high-strength steel.

Anodizing aluminum is a more environmentally-friendly process than electroplating, and it’s a great choice for many applications. Electroplating is an extremely common finishing process, but it is not considered an environmentally-friendly process. Thanks to technological developments, environmentally conscious alternatives have been created. Physical vapor deposition and powder coating have both gained popularity in the last few years. This article describes how these two processes differ and how they affect your products.

Another advantage of anodizing aluminum is that it uses less electricity. The energy consumed in electroplating aluminum is much lower than the power used in the anodizing process. Additionally, anodizing aluminum is more economical. It requires less maintenance than electroplating aluminum. Aside from being more economical, it is also more environmentally friendly. This article provides a few ways on how anodizing aluminum can be more environmentally-friendly than electroplating.

It is more durable than electrosprayed

Anodizing aluminum offers a number of advantages. For one thing, it has a higher degree of resistance to wear and corrosion. When aluminum is exposed to chlorides and environments outside of its normal pH range of four to nine, it will breakdown more quickly. A good example of this type of environment is concrete, which has a pH level of 12.5 to 13.5. Anodizing aluminum helps prevent this type of breakdown.

The process of anodizing aluminum is not labor intensive, as technicians do not need to apply a chemical to the aluminum surface. Instead, it takes advantage of a natural chemical reaction on aluminum. A high-amperage low-voltage electrical current is applied to the aluminum and an oxide layer forms, which is much thicker than the natural aluminum layer. As the chemical reaction occurs, the resulting layer of aluminum is harder than it would be otherwise.

Another difference between anodizing and electrospraying aluminum is the process. Anodizing creates an oxide film on the surface of aluminum that is much stronger than the raw metal. It is an integral part of the aluminum and does not sit on the surface, and it is more resistant to wear and scratching than electrosprayed aluminum. Additionally, anodizing is more environmentally friendly than electroplating.

It is more reflective than etched

Unlike etched aluminum, which is highly reflective, anodized aluminum will not lose its color if treated with acid etching. The acid etching process removes most irregularities in aluminum, but not all. Eco-friendly etching is better for the environment and provides a better aesthetic finish. Both etched and anodized aluminum have their own advantages, but anodizing is more reflective than etched aluminum.

When electrolytically etched aluminum, the process begins by immersing the part in a chemical bath. The electrodes attract aluminum atoms to the surface of the metal. The aluminum surface forms pits that allow for secondary processes to occur. The more pits formed, the more reflective the anodized aluminum is. But before applying the acid to the aluminum, it is important to note that the copper is not etched.

The process is cheaper than etched aluminum. The process requires a longer time than PVDF paints, but the result is more reflective and durable. Also, it is easier to apply paint primers and glues, which improves adhesion. Anodizing prevents galling, which is a form of wear caused by adhesion between two surfaces. It may tear the crystal structure beneath the surface.

The difference between etched and anodized aluminum comes from the depth of the pores in anodized aluminum. The deeper pores allow for a more reflective coating that lasts longer. Another difference between the two is the color. Anodized aluminum is more reflective than etched aluminum because of the deeper pores. It is more reflective than etched aluminum and has better protection against ultraviolet rays. The coating is also recyclable.

Anodized aluminum is more reflective than etched aluminum because the surface is not etched and does not have a crystalline structure. The surface is coated with a thin layer of metal, which provides excellent heat and corrosion resistance. This process is very fast and efficient, which makes it popular for small and medium-sized products. The main benefit of anodizing aluminum is its increased durability.

English

English Deutsch

Deutsch Français

Français 日本語

日本語