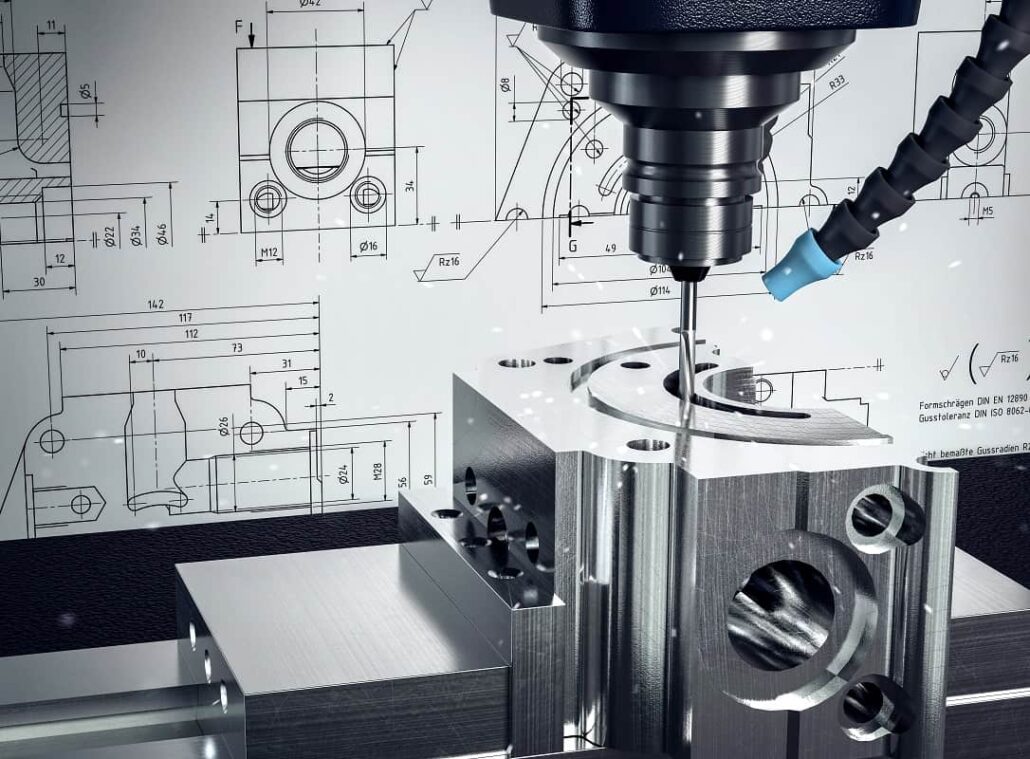

Advantages Of CNC machining Stainless Steel

1. The number of fixtures is greatly reduced, and complex fixtures are not required to process parts with complex shapes. If you want to change the shape and size of stainless steel parts, you only need to modify the part processing program, which is suitable for new product development and modification.

2. The processing quality is stable, the processing accuracy is high, and the repetition accuracy is high, which is suitable for the processing requirements of aircraft.

3. The production efficiency is higher in the case of multi-variety and small-batch production, which can reduce the time for production preparation, machine tool adjustment and process inspection, and the cutting time is reduced due to the use of cutting volume.

4. It can process complex profiles that are difficult to process by conventional methods, and even process some unobservable processing parts. The disadvantage of CNC stainless steel parts processing is that the machine tool equipment is expensive and requires a high level of maintenance personnel.

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español