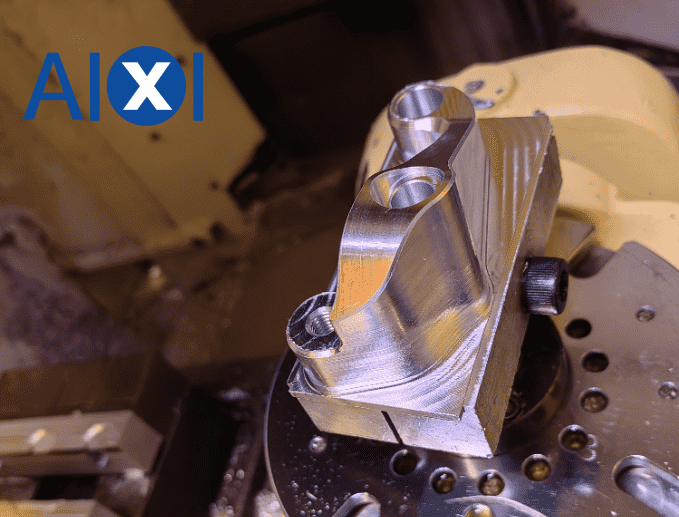

High Precision & Cost Effective CNC Aluminum Machining Parts Manufacturer

In the early days of AIXI, there was actually a period of time when our factory only provided CNC machining services for aluminum materials. The surface hardness of aluminum materials is low, and high-power machines and equipment are not required. We only need to have common three-axis and four-axis machines to provide complete processing for most CNC aluminum parts. Compared to steel materials, the tools used to process aluminum materials have a longer service life. Single aluminum material processing is a very good choice for start-up companies.

AIXI has been processing aluminum materials for a long time, and we have rich experience in producing higher quality custom aluminum parts. After all aluminum materials are CNC machined, we will process the surface separately to make the overall look consistent, without knife marks, and smoother.

The surface of aluminum materials is very fragile, and it is easy to leave scratches when it comes into contact with the waste residue left by processing. So every time a step is completed (for example, CNC Turning Machining -> CNC Milling Machining -> Anodizing -> Packaging), we must use soft materials for protection.

Now AIXI has become a mature CNC machining service supplier. We have a complete range of lathes, three-axis, four-axis, five-axis and other large equipment, we can not only process aluminum parts of a few millimeters, but also provide five-axis processing for products up to 800mm. Stainless steel, brass, plastic and other materials are now also our areas of expertise.

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español