Hello , if you can’t find a good color for anodized , you also can tell us the Pantone code, we can buy Pantone code color then anodized same color . More surface finsihing we can offer .

Category Archives: Surface Finishing

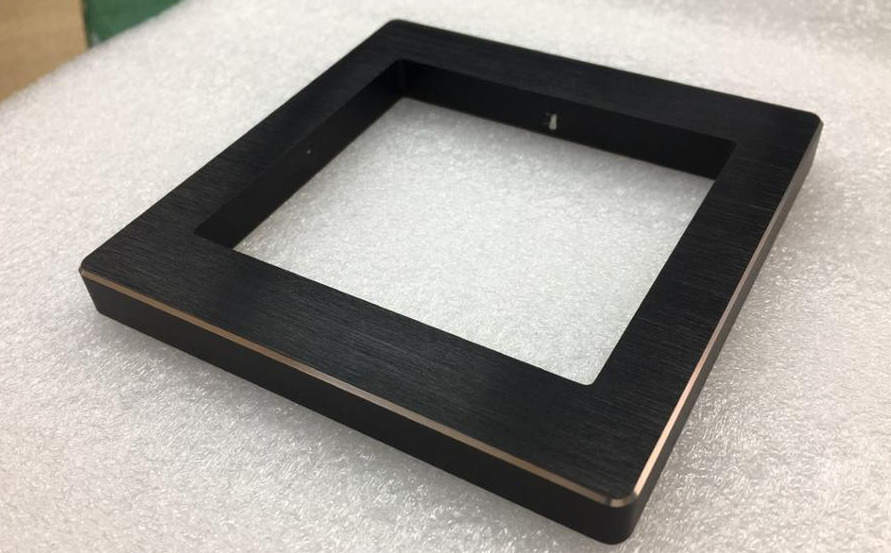

Anodized, powder coating, plating, painting, slik-screen, laser logo, polishing, brush.

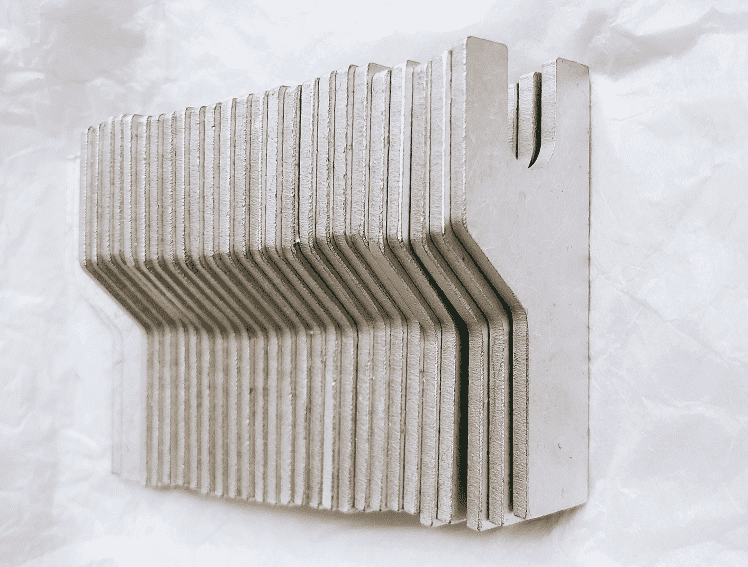

Why always have a bad surface for some factory ? not smotth . Because they only rough cnc machining the surface , and no precision milling it . maybe this is why always have a very lower price in China . because they delete lot of cnc work . For AIXI hardware , we will…

Advantages of powder spraying: a) High construction efficiency. For large-area operations, the construction staff can install multiple electrostatic spray guns and spray multiple at the same time, which can effectively shorten the spraying time and improve the spraying efficiency; b) Powder spraying is the corona discharge of the electrostatic spray gun to make the powder…

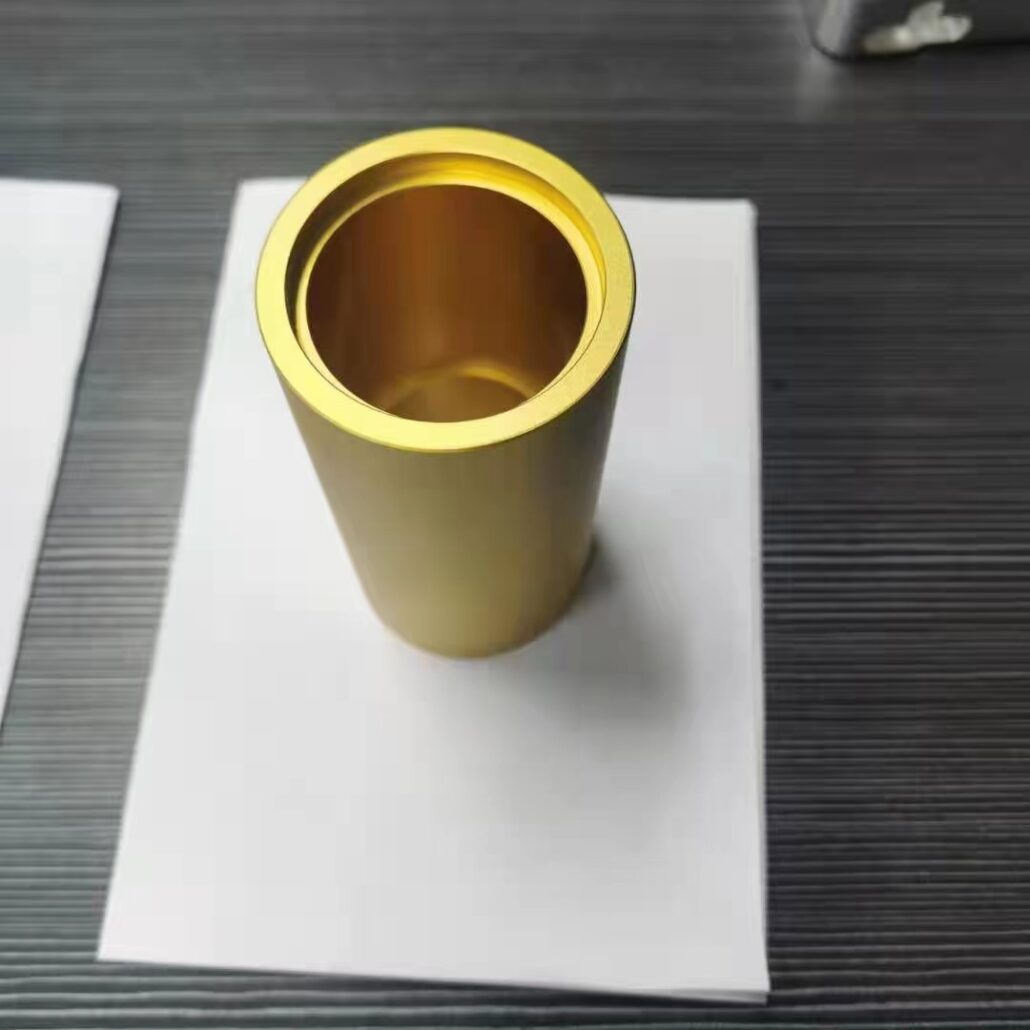

Copper tin plating can deposit a layer of bright metallic tin on the surface of copper. Copper-based electroless tin plating solution is mainly used for electroless tin plating of copper to increase the welding performance and decoration of copper. Used in the electronics industry, household appliances, food packaging, with anti-oxidation, increasing the beauty of copper…

The difference between hard anodizing and ordinary anodizing: Advantages of aluminum alloy hard oxidation: 1. The surface hardness of aluminum alloy after hard oxidation can reach up to about HV500. 2. The oxide film thickness is 25-250um. 3. Strong adhesion, according to the oxidation characteristics of hard oxidation: 50% of the formed oxide film penetrates…

Electroplating is the process of plating a thin layer of other metals or alloys on the surface of certain metals using the principle of electrolysis. According to the composition of the coating, the electroplating process can be divided into five categories: chrome plating, copper plating, cadmium plating, tin plating, and zinc plating. 1. Chrome plating…

Microplasma oxidation (MPO), also known as micro-arc oxidation, is a combination of electrolyte and corresponding electrical parameters. It grows on the surface of aluminum, magnesium, titanium and their alloys by the instantaneous high temperature and high pressure generated by arc discharge Ceramic film mainly composed of base metal oxide. In the process of micro-arc oxidation,…

The special process of spray coating application uses a special process to form a 0.5–1mm thick coating on the surface of the equipment. The coating has the following characteristics: 1. The coating and metal sound have extremely high binding force: the external force can not be removed basically, which solves the defect that the traditional…

The particularity of the wire processing industry makes the requirements of the copper plating process different from the conventional copper plating of steel parts. Therefore, how to choose a copper plating process suitable for wire processing is a very important subject. Generally, the basis for selecting the plating process is first of all the requirements…

Because aluminum is widely used because of its easy processing, good visual effect and rich surface treatment methods, how much do you know about the surface processing technology of aluminum and aluminum alloy in daily products? Brushed rivets and lantern rivets are made of aluminum alloy. Aluminum itself has a waterproof and anti-corrosive effect, while…

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español