Aluminum has many excellent properties. Its cost-effectiveness makes it suitable for many manufacturing projects. However, its corrosion resistance and aesthetics are not as good as one would love. So, many manufacturers put this material under an anodizing process. But do you know: what is aluminum anodizing? I know that this concept is well understood….

Category Archives: Surface Finishing

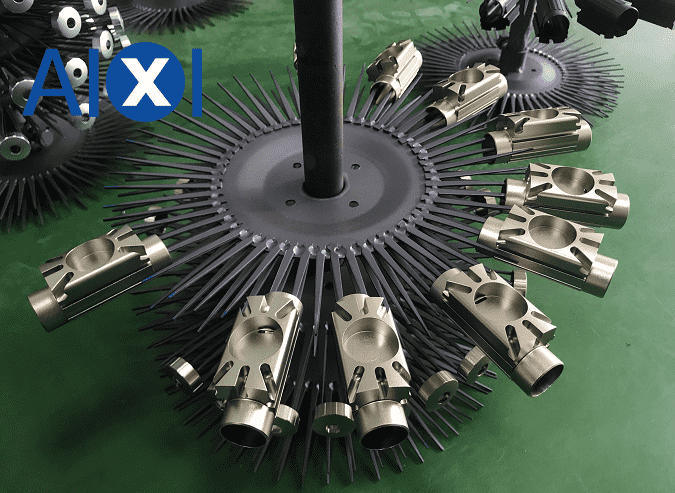

Anodized, powder coating, plating, painting, slik-screen, laser logo, polishing, brush.

In this competitive world, perfection is paramount. A minor flaw can affect the whole reputation of products and companies. However, CNC machines offer a high level of perfection that satisfies customers. Surface roughness in CNC manufacturing is something that ensures precision. In simple words, surface roughness is the critical factor that controls the precision….

Chrome-plated and anodized are two common metal surface treatment processes, and they are significantly different in purpose, principle, and application scenarios. The following is a detailed comparison of these two treatment processes: 1. Definition and Principle 1.1. Chromium plating: Chromium plating is a process of depositing a chromium layer on a metal surface…

All post-processing adds to part production costs and production time, but the right surface finish can go a long way toward making the original design vision a reality. Metal surface treatments for CNC machined parts typically include various mechanical processes such as tumbling, brushing, and sandblasting, but metal parts can also have chemical surface treatments…

As the economy develops and the consumption structure continues to upgrade, consumers have higher requirements for the appearance and quality of various products, pay more attention to quality, and present the characteristics of personalized, diversified, high-end, and experiential consumption. Therefore, the surface treatment of workpieces in our hardware industry has become particularly important, not only…

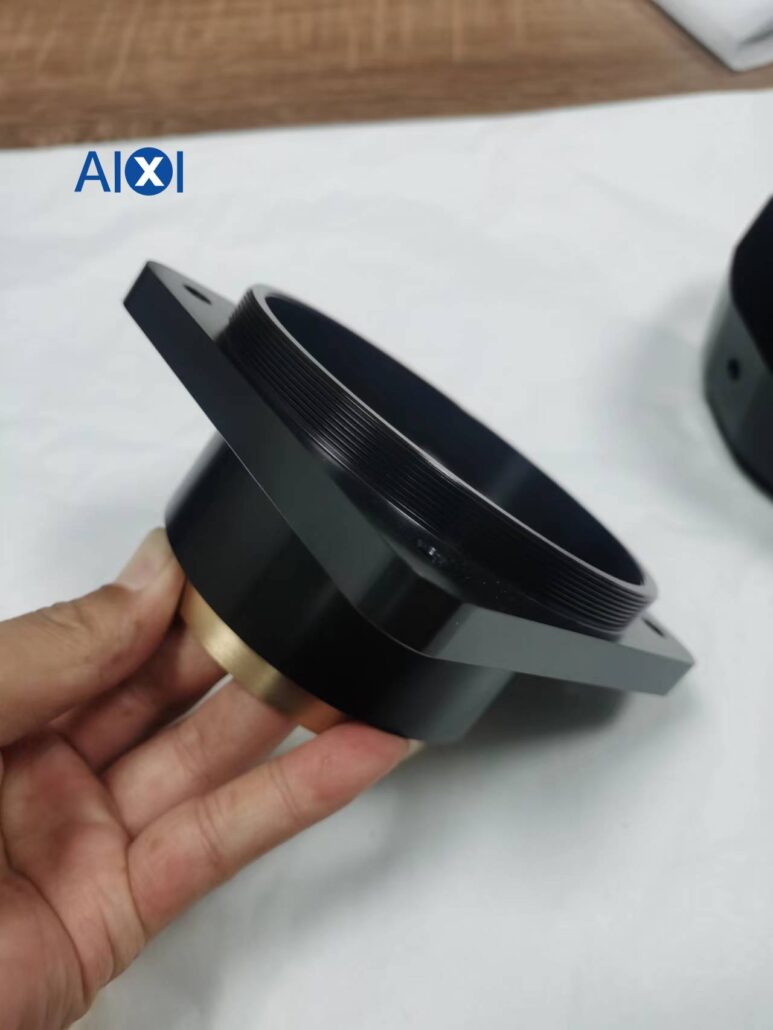

Anodizing: Electrochemical oxidation of metals or alloys (most anodizing is done on aluminum and its alloys). Aluminum and its alloys form an oxide film on the aluminum product (anode) under the corresponding electrolyte and specific process conditions due to the action of the applied current. Anodizing generally refers to sulfuric acid anodizing. Alodine treatment: Aluminum…

Do you know how to control the hard oxidation time? Anodizing time is too long. It is easy to cause loosening and falling off. The film layer is rough. Anodizing time is too short. .The film is thin and smooth. It can be seen that too long or too short anodizing time is not good…

Surface treatment technology and function of CNC machining (lathe, CNC milling machine) parts, cost of surface finish For each product, specific surface treatments are available for CNC machined parts. However, the surface finish of the product tends to add a corresponding cost. Some finishes, such as high polish, are designed to remove any marks from…

What Is Anodized Aluminum? If you’re wondering, “What is anodized aluminum?” you’re not alone. The term has been used in many contexts. In this article, we’ll explore the meaning of this word. This unique process produces the beautiful, hard-wearing surface of many aluminum products. In a nutshell, anodized aluminum is a protective coating applied to…

Aluminum is a popular material, and manufacturers prefer it due to its lightweight. However, it has some drawbacks, like limited rust protection and durability. So, it undergoes an anodizing process so that manufacturers get the desired rust protection. This raises the question of whether anodized aluminum is better than regular aluminum. You might argue…

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español