Common Process and Problem Analysis The laser beam input from the melt-cutting perforation technology has high power density and high energy. The inside of the material at the beam irradiation point begins to evaporate, forming a hole. The small hole is surrounded by molten metal, and the auxiliary airflow coaxial with the beam surrounds the…

Category Archives: Sheet Metal Services

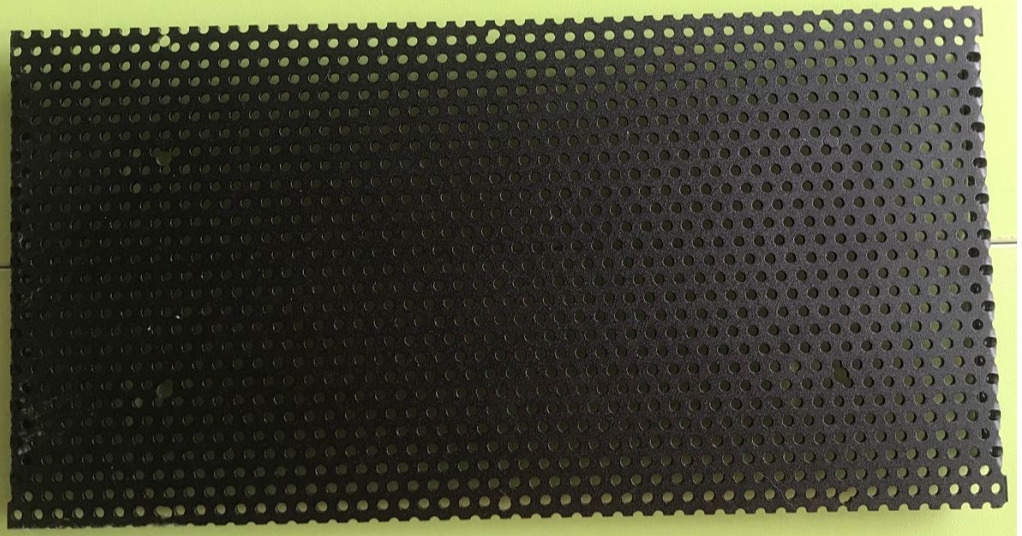

For the audio industry hot market , sheet metal processing is very popular now , because compare cnc machining , sheet metal is cheaper and useful.

Nowadays, Shenzhen laser cutting processing technology is popular in the market. It is very popular among consumers. Among them, metal laser seven is a common laser cutting processing method. How much do you know about it? How to deal with it? Let’s take a look at our Shenzhen laser cutting factory. 1, melt cutting When…

Sheet metal processing is actually the processing of metal products, and it is more to modify the metal sheets to achieve their use in many different places. It is processed in many ways, including stamping, cutting, cutting, etc. to change the properties and shape of the metal. The use of this processing technology can bring…

3D Printing Metal, 3D Printing Plastic, Audio Industry, Automotive Industry, Bend Tube/Pipe, BLOG, CNC Machining, Die Casting, Extrusion Services, Fastener Parts, Gear Processing, Headphone Industry, Injection Tooling, Laser Cutting, Material Knowledge, Metal Material, Plastic Material, Quality Assurance, Rapid Prototyping, Sheet Metal Services, Stamping Services, Surface Finishing, Thermoforming, Turning & Milling Machining, Uncategorized, Vacuum Casting, Welding Knowledges, Wire Cutting

Talk the surface treatment

1: anodizing In order to enrich the color of the product, we can usually make some oxidation treatment. The oxidation treatment can make all the colors except white. The oxidation treatment is done for the aluminum alloy. If it is other materials, it can’t make anodization. Steel material, you can choose plating, etc. anodized aluminum,…

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español