In the process of sheet metal processing, usually after the blanking is completed, the next process is entered, and different workpieces enter the corresponding process according to the processing request. There are bending, pressure riveting, flanging and tapping, spot welding, bumping, and step difference. Sometimes the nut or stud should be pressed after bending one…

Category Archives: Sheet Metal Services

For the audio industry hot market , sheet metal processing is very popular now , because compare cnc machining , sheet metal is cheaper and useful.

For the sheet metal processing industry, it is no longer the time for an enterprise to work on its own, because the mechanical processing industry is an ancient industry, and the mechanical processing industry has developed since a long time ago, and sheet metal processing is in the sheet metal processing industry. After the emergence…

The processing steps of the processed parts in the sheet metal workshop are: product preliminary test, product processing trial production and product batch production. In the process of product manufacturing trial production, you should communicate with customers in time and get the corresponding processing evaluation before proceeding to mass production of products. Laser drilling technology…

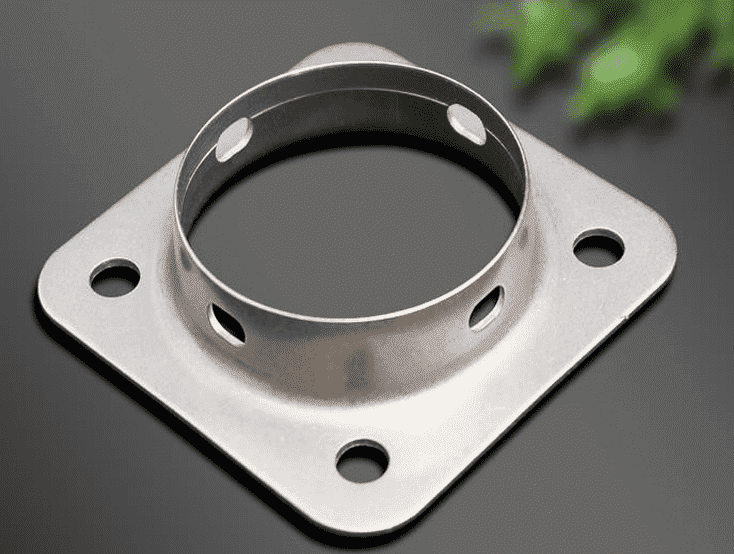

According to the basic processing method of sheet metal parts, such as cutting, bending, stretching, forming and welding. This specification describes the process requirements to be noted for each processing method. Blanking According to the different processing methods, the cutting can be divided into general punching, number punching, shearing machine cutting, laser cutting, and wind…

Sheet metal processing has always been an important part of the metal manufacturing industry. With the rapid development of China’s economy in recent years, China’s sheet metal processing industry is also booming. However, compared with foreign sheet metal processing models, due to the late start of sheet metal processing in China, there are still certain…

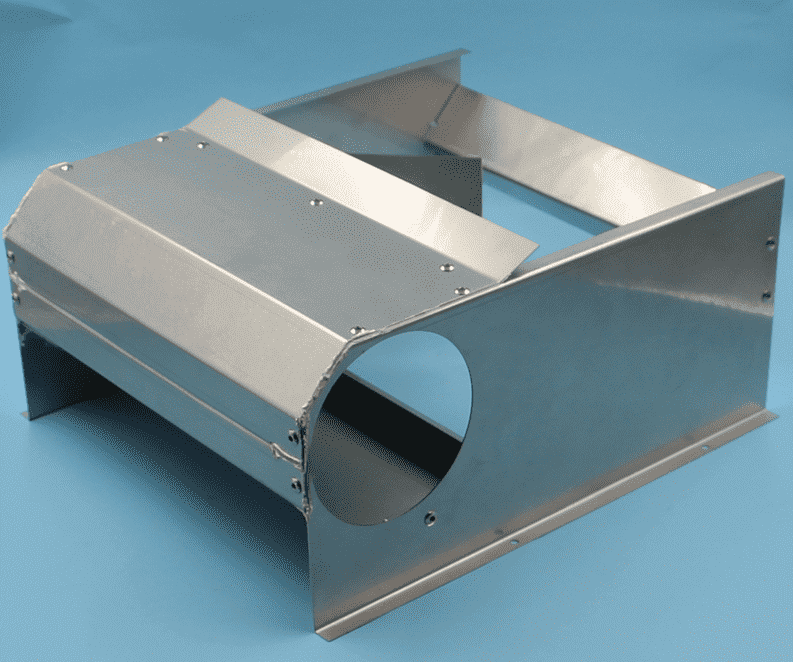

Sheet metal processing cabinets are classified into equipment cabinets and wiring cabinets by function. In the design of sheet metal cabinet processing, we must not only consider the use of sheet metal cabinets, but also adjust the space design and adjustment of sheet metal according to the equipment assembly of sheet metal cabinets. Load capacity….

The production process of sheet metal parts is relatively cumbersome, so how should we assemble the sheet metal products after molding? What should we pay attention to when assembling? The following is introduced in detail by the editor, I hope to help everyone. 1. Before assembly, we should carefully read the assembly process and packing…

Sheet metal processing is generally to plastically deform some metal sheets by hand or die stamping to form the desired shape and size, and can further form more complex parts by welding or a small amount of mechanical processing; sheet metal processing has been Our lives are closely related. It is an imperative development trend…

The processing of the surface of the sheet metal chassis is commonly used: cold plate, hot plate, stainless steel plate, galvanized iron sheet, with different appearance processing skills. The cold plate and hot plate can be used as powder or paint. Before the powder, it is necessary to ensure that there is no oil coating…

How should you choose sheet metal Shouban customization? Sheet metal Shouban customized new products need to do Shouban model customization when they are just beginning to be developed. So what are the ways to customize the new product model of the new product? One is to verify the appearance. The second is the verification function….

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español