How Thin Can You CNC Aluminum? If you’ve ever wondered how to CNC aluminum, you might have wondered whether you should use straight-flute bits or fluted end mills. While both types of cutters can cut aluminum, wood can be faster to cut. However, wood can suffer from Radial Chip Thinning if you cut it less…

Category Archives: CNC Machining

We will share cnc machining knowledges , if you are interiesting for us , welcome focus on our website , and i believe you can learn you want .

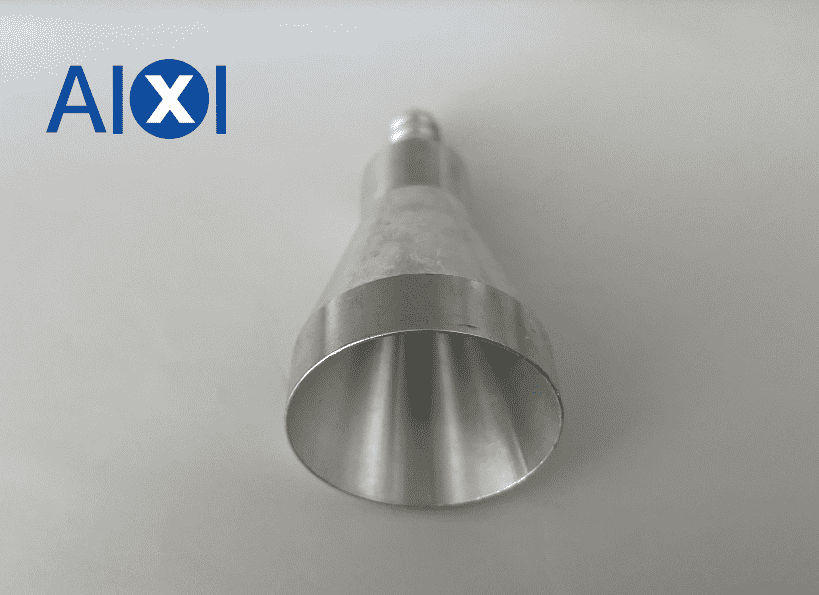

Can You CNC 6061 Aluminum? There are many different alloys made from aluminum, but there is one grade that is particularly well-suited for CNC machining: 6061. This grade of aluminum is commonly called “tooling plate” and has the right properties to maintain a high level of flatness. However, 6061 is still the most popular aluminum…

CNC aluminum is famous for its strength. Its usage is a staple in many industries, including aerospace and automobiles. However, the buyers remain confused about the strength of CNC aluminum during the selection process. So, they ask: how strong is CNC aluminum? CNC aluminum has an exceptional tensile strength of 180 Mpa. It indicates…

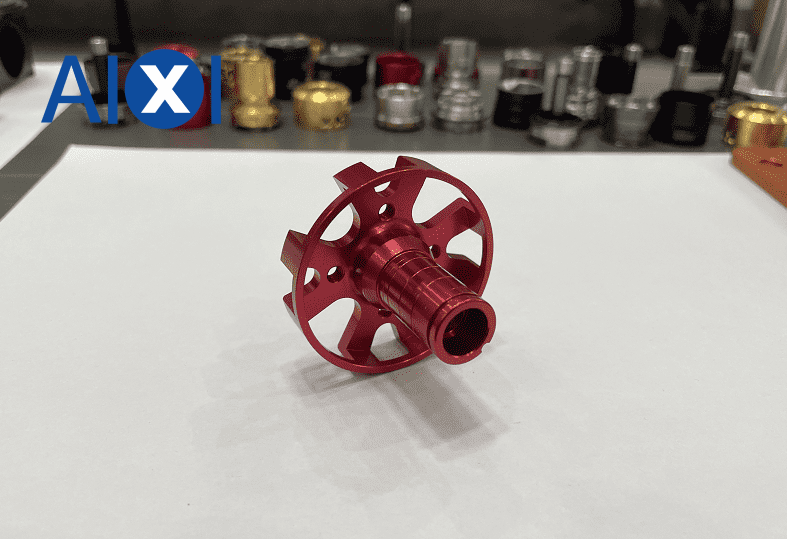

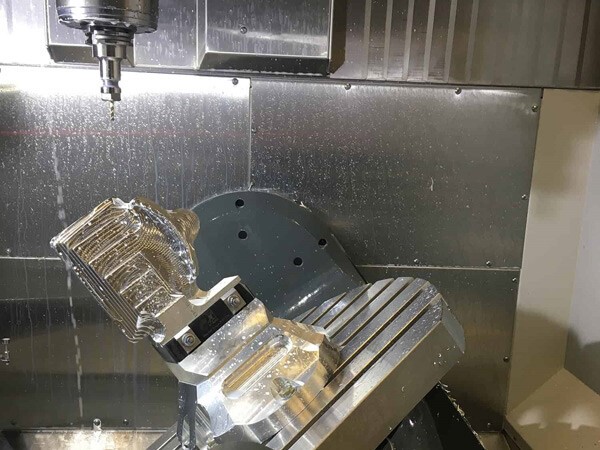

Can You CNC Aluminum? Can you CNC aluminum? Yes, you can. However, there are several things to keep in mind. Aluminum is extremely difficult to cut and requires high-quality tooling. Here are a few tips for cutting aluminum. First, don’t forget to lubricate the cutting tool. Aluminum will stick to the bit if it’s not…

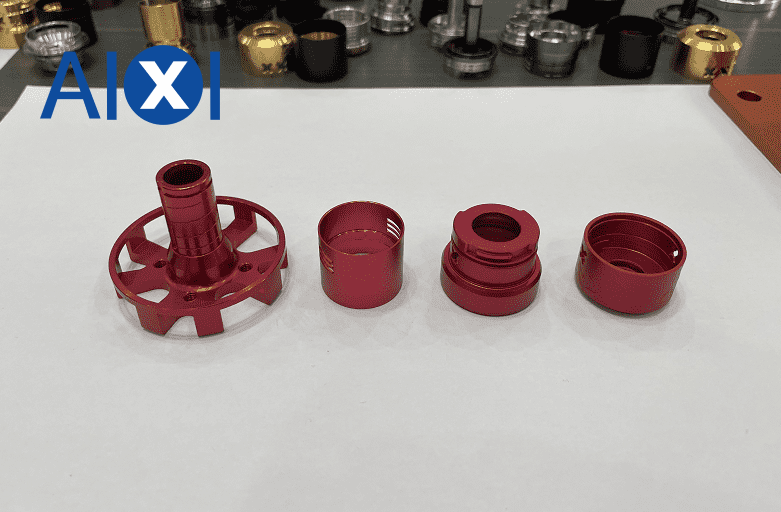

What Is CNC Prototyping? CNC aluminum prototyping is a popular method for creating prototypes. The process is mostly automated and requires little manual work, but a well-experienced user can still be an invaluable asset in creating a high-quality part. An experienced user will also be aware of the intricacies of different materials, as well as…

Is Aluminum A Common Prototyping Material? If you’re a product designer, you’re probably wondering, “Is aluminum a common prototyping material?” If so, you’re not alone! Aluminum is often used for prototype manufacturing due to its outstanding qualities, including corrosion resistance and strength. This makes it a highly suitable choice for various projects, from pre-production prototypes…

According our experience : 1: Quote speed If quantity lower 10 products , can’t quote within 8-10hours , it means can’t reply within working day , i think this is not real factory , most likely is a trade company , because they need wait other company quote , then quote to customer . so…

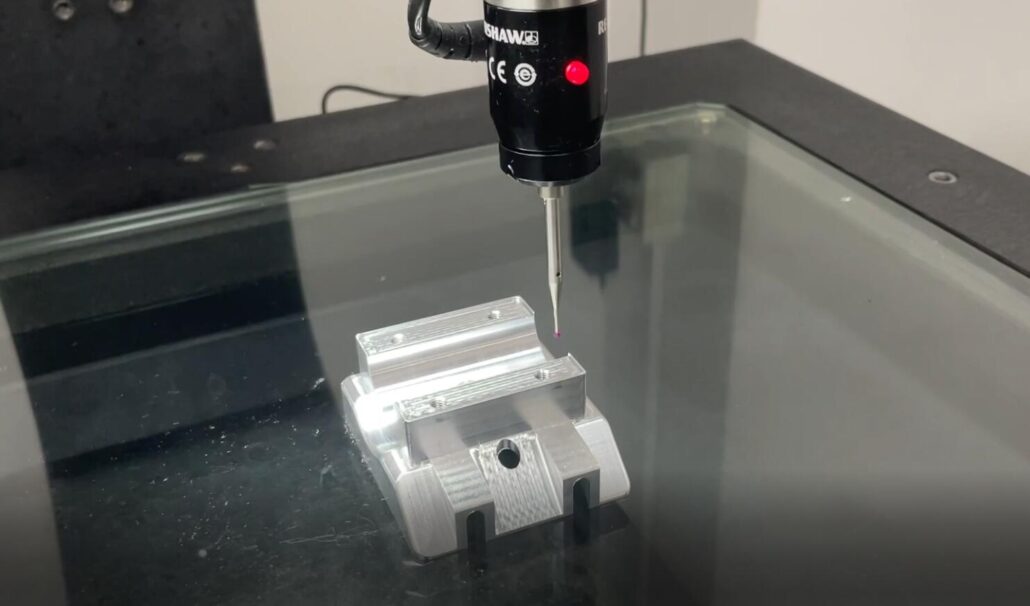

CNC precision machining can manufacture a variety of complex parts with high precision. Machines and tools that can be mastered through CNC machining include lathes, grinders, and mills. CNC or computer numerical control allows extremely specific control over the positioning, speed, blending, feed rate and other precision aspects of the manufacturing process for a particular…

The reason why CNC precision machining is called precision machining is that its processing procedures and processing requirements are very high, and the precision requirements of products are also very high, and the machining accuracy of precision parts includes: position accuracy, dimensional accuracy, style accuracy, etc., The components that affect the precision of precision parts are…

In the process of processing, every process is very critical. If there is a process that is not operated in time due to carelessness in the process of processing, it is very likely to immediately endanger the final actual effect of the product. Therefore, in the process of work, the operating staff must be very…

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español