Top Aluminum – Cost-effective Processing of Aluminum Parts If you are looking for a high-quality, high-precision, and fast aluminum CNC machining product manufacturer. You can trust Ashe to be your best choice. We have several high-end five-axis linkage CNC machine tools (a machine tool with high technological content, high precision, and dedicated to processing complex…

Category Archives: CNC Machining

We will share cnc machining knowledges , if you are interiesting for us , welcome focus on our website , and i believe you can learn you want .

The Importance of Machining Tolerances in the Manufacturing Industry Tolerance matching in mechanical manufacturing is a rigorous and complex work, which requires the full attention of mechanical designers and manufacturers. In today’s society, people’s requirements for quality are extremely high. Therefore, in the process of any product manufacturing process, the standard processing tolerance is an…

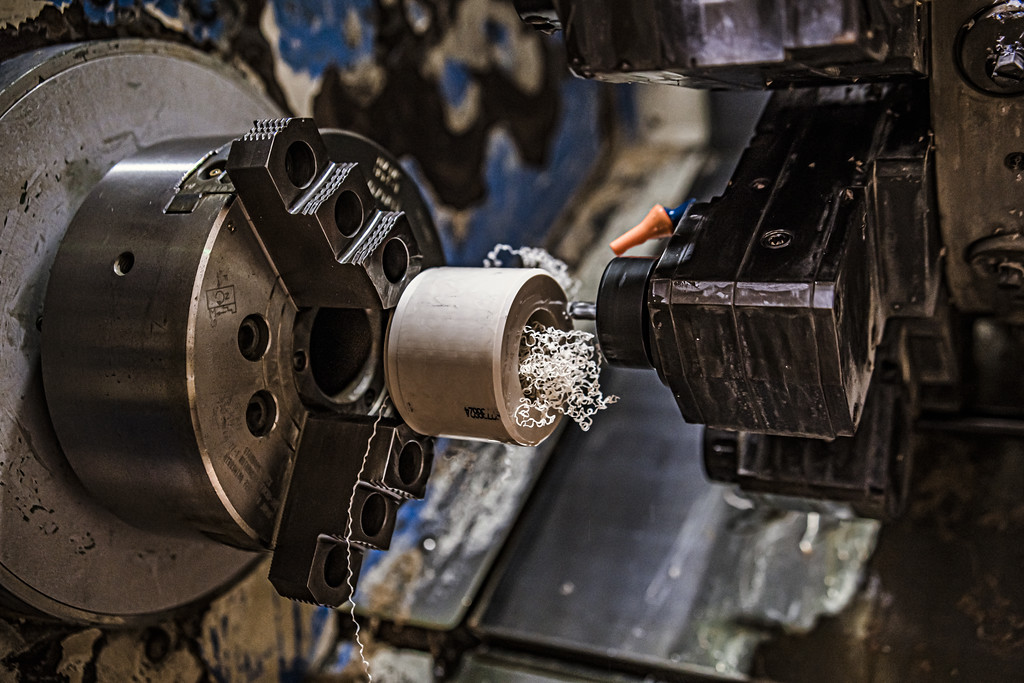

What are CNC? How does it work? CNC is an acronym for Computer Numerical Control. It is a pre-programmed computer software that directs the operation of factory equipment and machinery. Use subtraction to remove unnecessary parts from a large block of material. Before the advent of CNC machines, the industry operated using manually controlled handwheels…

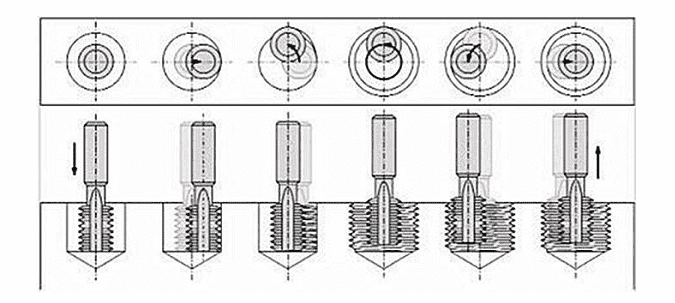

A threaded rod, also known as a screw or stud, is a cylinder with helical grooves cut into its outer surface or a cone with helical grooves cut into a conical surface, and has threads along its entire length. The screws have different heads, such as outer hexagonal screws, large flat screws, inner hexagonal screws,…

Machining is a process of changing the shape or performance of workpieces with processing machinery. Remove excess material in a controlled manner to produce the desired part. Therefore, machining is also called subtractive manufacturing, and the workpiece is always larger than the finished part. Machining processes allow for greater precision than alternative technologies such as…

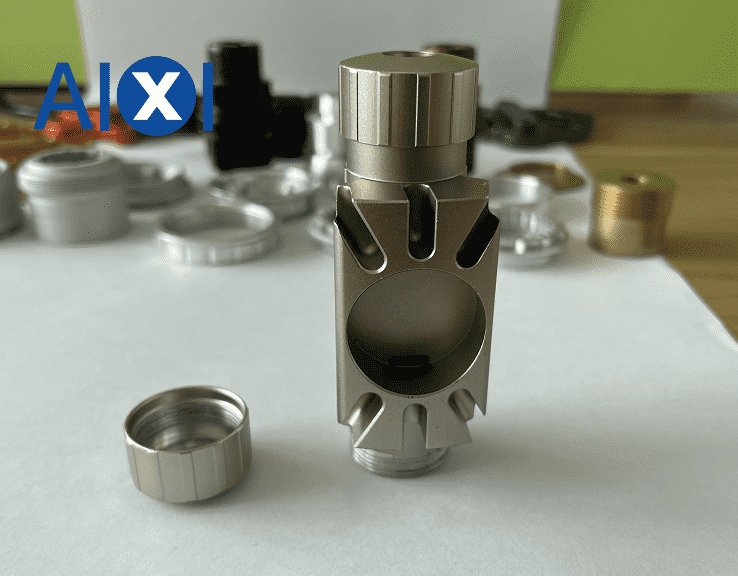

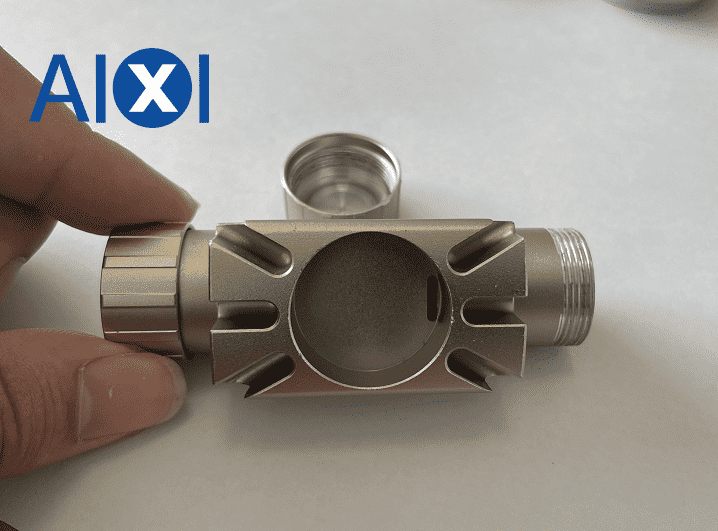

On-demand production (not limited by batches, saving costs in the R&D stage) Custom aluminum products are ideal for moving a client’s design from the imagination stage to the prototyping stage. Customization is a special service and is not limited by batches. We can accept 1 MOQ when the customer is still in the design and…

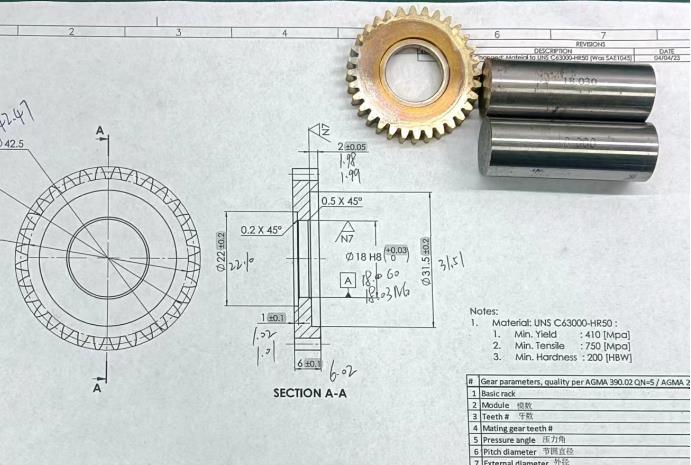

About C63000: ASTM B150 UNS C63000 is aluminum bronze, which has high strength and good wear resistance. It is used for relatively high-strength screws, nuts, copper sleeves, sealing rings, etc., and wear-resistant parts. The most prominent feature is its good wear resistance. Aluminum bronze generally does not contain more than 11.5% aluminum, and sometimes an…

AIXI Hardware have rich experience offer online CNC machining serivces, 15 years experience in supplying CNC online custom parts worldwide. We can offer online CNC milling, turning, driling, EDM machining service, for material, we can do CNC aluminum (6061-T6, 7075-T6, 6063, 5052), Brass, Stainless Steel (303, 304, 316, 316L, 1.4301, 1.4305, 17-4PH, SS630), POM, PP,…

CNC machining generally refers to computer digital precision machining, CNC machining lathes, CNC milling machines, and CNC machining iron beds. It is an automatic machine tool equipped with program control. Computer numerical control machine tool is a programmable control automatic machine tool. cnc processing knowledge Create CNC process functions and CNC machining process plans: (1)…

In the turning process of threaded parts, due to the wear and tear of the thread tool, it is often necessary to reload the tool and set the tool. The quality of the tool setting will directly affect the accuracy of thread turning, especially the thread repair turning. , requires secondary clamping and secondary tool…

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español