Anodizing: Electrochemical oxidation of metals or alloys (most anodizing is done on aluminum and its alloys). Aluminum and its alloys form an oxide film on the aluminum product (anode) under the corresponding electrolyte and specific process conditions due to the action of the applied current. Anodizing generally refers to sulfuric acid anodizing. Alodine treatment: Aluminum…

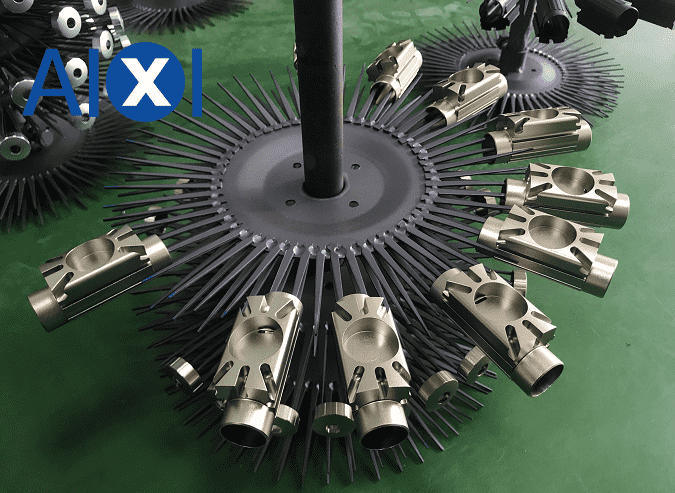

On-demand production (not limited by batches, saving costs in the R&D stage) Custom aluminum products are ideal for moving a client’s design from the imagination stage to the prototyping stage. Customization is a special service and is not limited by batches. We can accept 1 MOQ when the customer is still in the design and…

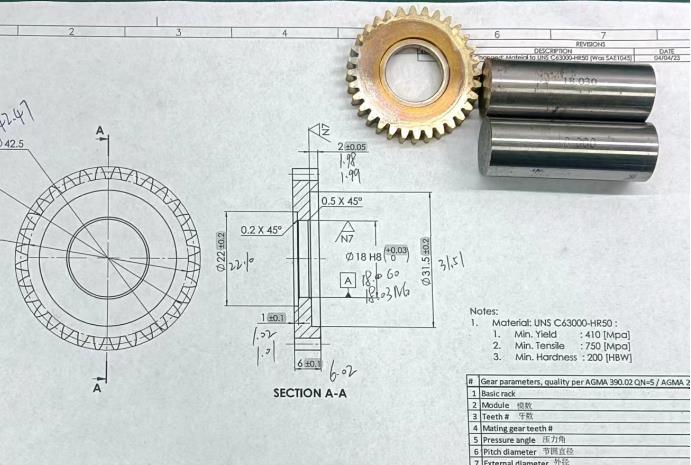

About C63000: ASTM B150 UNS C63000 is aluminum bronze, which has high strength and good wear resistance. It is used for relatively high-strength screws, nuts, copper sleeves, sealing rings, etc., and wear-resistant parts. The most prominent feature is its good wear resistance. Aluminum bronze generally does not contain more than 11.5% aluminum, and sometimes an…

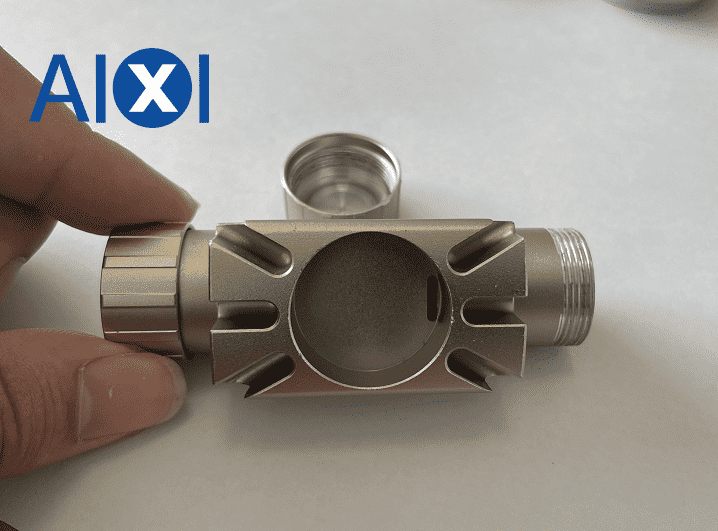

AIXI Hardware have rich experience offer online CNC machining serivces, 15 years experience in supplying CNC online custom parts worldwide. We can offer online CNC milling, turning, driling, EDM machining service, for material, we can do CNC aluminum (6061-T6, 7075-T6, 6063, 5052), Brass, Stainless Steel (303, 304, 316, 316L, 1.4301, 1.4305, 17-4PH, SS630), POM, PP,…

Do you know how to control the hard oxidation time? Anodizing time is too long. It is easy to cause loosening and falling off. The film layer is rough. Anodizing time is too short. .The film is thin and smooth. It can be seen that too long or too short anodizing time is not good…

You might have heard of aluminum anodizing a few times before. It gives the metal surface a final look and adds to its longevity. Yet, the question is: how is it done? What is anodized aluminum? Or is it important to opt for anodizing aluminum? Well, whatever your question, here is everything to explain about…

CNC machining generally refers to computer digital precision machining, CNC machining lathes, CNC milling machines, and CNC machining iron beds. It is an automatic machine tool equipped with program control. Computer numerical control machine tool is a programmable control automatic machine tool. cnc processing knowledge Create CNC process functions and CNC machining process plans: (1)…

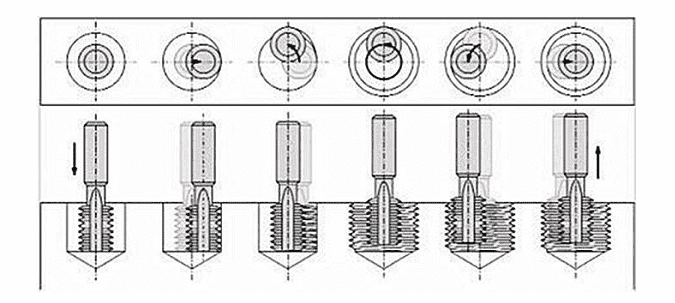

In the turning process of threaded parts, due to the wear and tear of the thread tool, it is often necessary to reload the tool and set the tool. The quality of the tool setting will directly affect the accuracy of thread turning, especially the thread repair turning. , requires secondary clamping and secondary tool…

Differences between ABS plastic and POM: 1. The characteristics of the two are different: 1. Characteristics of ABS plastic: ABS has excellent composite physical and mechanical functions and particularly good low temperature impact resistance. Dimensional stability. Electrical performance, abrasion resistance, chemical resistance, dyeing, finished product processing and mechanical processing are all good. ABS resin has…

17-4PH Executive standard: American ASTMS17400, ASTM A564 630, UNS630 17-4PH is a martensitic precipitation hardening stainless steel. In addition to directly obtaining martensitic structure after solid solution treatment, this steel is further strengthened by subsequent aging treatment-obtaining precipitation hardening phase (copper-containing phase). 17-4PH is a precipitated, hardened, martensitic stainless steel composed of copper, niobium/columbium. This…

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español