Thread processing is one of the most important applications of cnc machining centers. The quality and efficiency of thread processing will directly affect the processing quality of parts and the production efficiency of machining centers. With the improvement of the performance of cnc machining centers and the improvement of cutting tools, the method of thread…

1. Analysis and review of the drawings The analysis of the pattern is a decisive first step in ensuring the quality of the workpiece and the comprehensive technical specifications of the workpiece. Taking the blanking die as an example, when digesting the pattern, it is first necessary to pick out the workpiece drawings that cannot…

Although many screw people know the category, shape, design, etc. of fasteners very well, the eager “screw man” has been looking for more comprehensive knowledge points. First, determine the category Standard fasteners are divided into ten categories. The selection should be based on the use of standard fasteners and their use. 1 Bolt: Bolts are…

Molding: the process of leaving the mold under the action of the ejection mechanism Beer: mold angle or draft angle Undercut: the position where the mold cannot be pulled out vertically because of the side angle or the concave position Die layout: the schedule of the mold Zheng Ge: A mold structure in which the…

Precision machining has tremendous advantages and has changed the way in many industries, including manufacturing, automation, robotics and the aerospace industry. But one of the most important industries for precision machining is the medical industry. Without the innovation and advancement of precision machining, many of the medical advances we enjoy today are impossible. Here, we…

In our product design process, sample run of precision machined parts is limited by some of the most rigorous inspection procedures. The test method we use proves to the customer that the part meets the specified tolerances and is free from defects. From magnetic particle inspection to laser scanning, we ensure that each new product…

We understand why the custom processing market is dominated by CNC machine tools. The main reason behind this is the versatility and repeatability of CNC machines. Traditional machines require a manual controller that is prone to small errors. However, the CNC machine is controlled by a computer that converts the cad model of the desired…

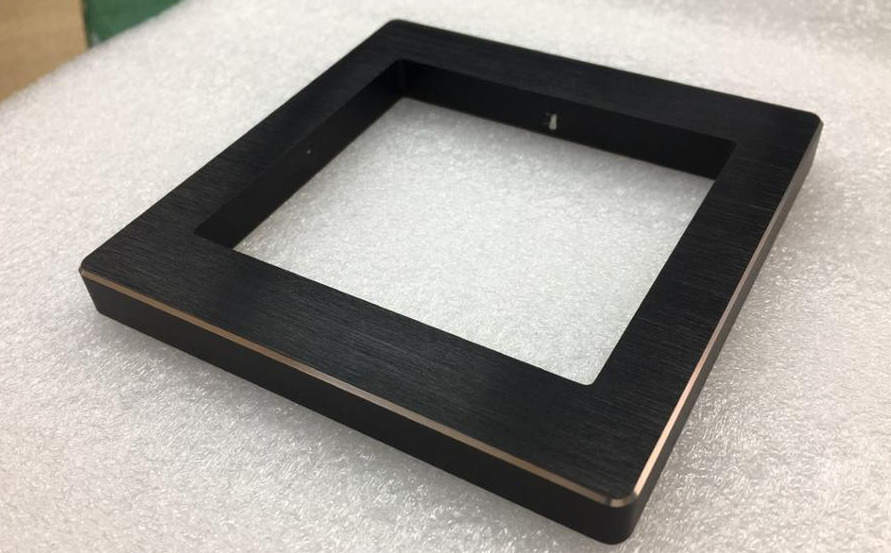

Because aluminum is widely used because of its easy processing, good visual effect and rich surface treatment methods, how much do you know about the surface processing technology of aluminum and aluminum alloy in daily products? Brushed rivets and lantern rivets are made of aluminum alloy. Aluminum itself has a waterproof and anti-corrosive effect, while…

Nowadays, most of the products in this society are processed by hardware accessories, but the steps of surface processing of hardware accessories may not be clear to everyone. The most common processing technology for hardware accessories processing is through modern technology. Development of the plating of the surface of the hardware accessories, to ensure that…

Compared with wet coating technology, vacuum coating technology has the following advantages: (1) The film and the substrate are widely selected, and the film thickness can be controlled to prepare a functional film having various functions. (2) The film is prepared under vacuum conditions, the environment is clean, and the film is not easily contaminated,…

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español