1. In order to prevent broken chips from hurting people, a transparent baffle should be installed in an appropriate position. 2. When you need to use gauze to polish the surface of the workpiece, move the tool to a safe position, and be careful not to let your hands and clothes touch the surface of…

With the rapid development of sheet metal processing technology, the domestic processing technology is also changing with each passing day, and the gap between the developed countries and foreign countries is getting smaller and smaller. Many well-known foreign-funded enterprises have moved their manufacturing bases to China. Many revolutionary ideas have come. As the traditional sheet…

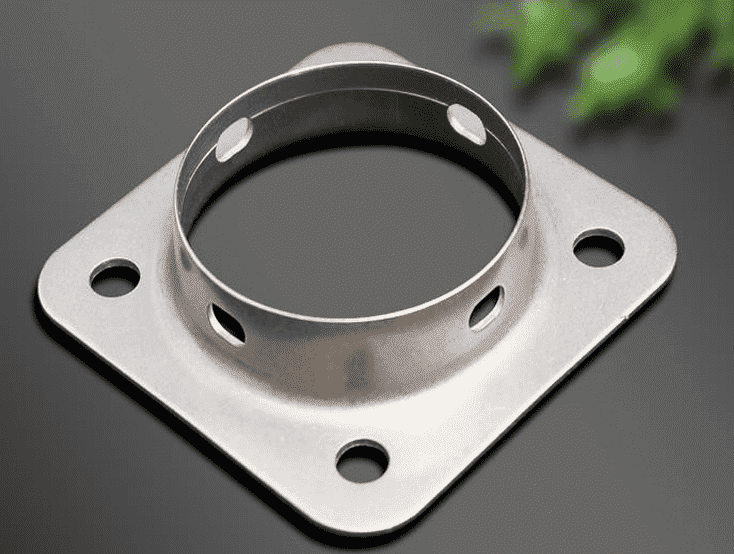

In the process of sheet metal processing, usually after the blanking is completed, the next process is entered, and different workpieces enter the corresponding process according to the processing request. There are bending, pressure riveting, flanging and tapping, spot welding, bumping, and step difference. Sometimes the nut or stud should be pressed after bending one…

For the sheet metal processing industry, it is no longer the time for an enterprise to work on its own, because the mechanical processing industry is an ancient industry, and the mechanical processing industry has developed since a long time ago, and sheet metal processing is in the sheet metal processing industry. After the emergence…

The processing steps of the processed parts in the sheet metal workshop are: product preliminary test, product processing trial production and product batch production. In the process of product manufacturing trial production, you should communicate with customers in time and get the corresponding processing evaluation before proceeding to mass production of products. Laser drilling technology…

According to the basic processing method of sheet metal parts, such as cutting, bending, stretching, forming and welding. This specification describes the process requirements to be noted for each processing method. Blanking According to the different processing methods, the cutting can be divided into general punching, number punching, shearing machine cutting, laser cutting, and wind…

The cnc four-axis machining center was first used in the processing of curved surfaces, that is, the processing of blades. Nowadays, the cnc four-axis machining center can be applied to the processing of polyhedral parts, spiral lines (cylindrical surface oil grooves) with spiral angles, spiral grooves, cylindrical cams, cycloid, etc., which are widely used. From…

1. Is a CNC machining center or an engraving and milling machine good? CNC machining center and engraving and milling machine are more commonly used mechanical equipment, the two also have similarities and differences, if it is hard to say whether the CNC machining center is good or engraving and milling is difficult to have…

At present, CNC high-gloss machining processes (milling, turning) are not well known to technicians in most industrial industries. Practice shows that they are only really controlled by a few consumer companies. The main reason is that the previous demand is not very strong, of course, this is also closely related to cognition. Today we are…

The particularity of the wire processing industry makes the requirements of the copper plating process different from the conventional copper plating of steel parts. Therefore, how to choose a copper plating process suitable for wire processing is a very important subject. Generally, the basis for selecting the plating process is first of all the requirements…

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español