Aluminum alloy materials are the most widely used non-ferrous metal structural parts in the industrial field, and are widely used in aviation, aerospace, automotive, machinery manufacturing, shipping, electronic machining, molds and chemical industries. Aluminum alloy materials are divided into different grades. Each grade material contains slightly different elements. Different grades are suitable for different ranges:…

PVC Chinese name: Polyvinyl chloride, a plastic blister made of this material, is a large amount. Due to its good transparency and easy to form, it is mainly used for small commodity packaging in supermarkets. Compared with other plastic materials, its cost is relatively low. And it is also suitable for heat sealing with ordinary…

Transmittance PC board can transmit light up to 89%, which is comparable to glass. The impact strength is 250-300 times that of ordinary glass, 30 times that of acrylic plates of the same thickness, and 2-20 times that of tempered glass. There is no crack when falling with a 2kg hammer below 3KG. There are…

Most of the transparent food blister products we see in supermarkets are made of BOPS materials. BOPS blister products have been used in developed countries for many years. It has good strength and strong resistance to tearing. It has good gloss and transparency than PET and PVC materials. It is non-toxic and tasteless, and has…

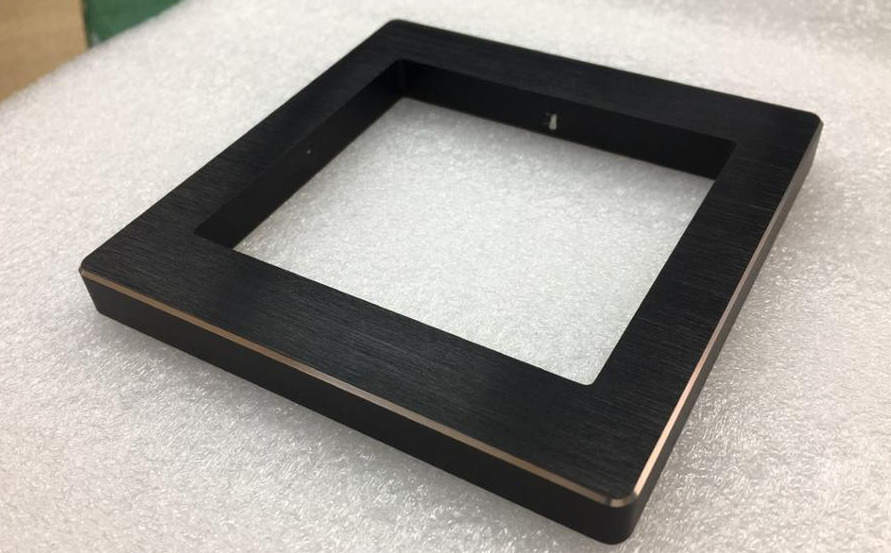

Microplasma oxidation (MPO), also known as micro-arc oxidation, is a combination of electrolyte and corresponding electrical parameters. It grows on the surface of aluminum, magnesium, titanium and their alloys by the instantaneous high temperature and high pressure generated by arc discharge Ceramic film mainly composed of base metal oxide. In the process of micro-arc oxidation,…

Mold temperature: The mold temperature has a great influence on the intrinsic performance and apparent quality of the product. The temperature of the mold depends on the crystallinity of the plastic, the size and structure of the product, performance requirements, and other process conditions (melt temperature, injection speed and injection pressure, molding cycle, etc.). Pressure…

The large-scale casting machine tool workbench is an important point of development in our country at present, and it is also one of the standard lines to measure the level of China’s foundry industry. The large-scale casting machine tool workbench is to melt metal into a liquid that meets certain requirements and pour it into…

It is of great significance to correctly understand the connotation of the surface quality of parts, analyze various technological factors that affect the quality of the processed surface during the machining process, and improve the surface quality and product performance. The surface quality of mechanical processing refers to the micro unevenness of the processed surface…

Special-shaped sheet metal processing also has a high appearance rate among manufacturers of mechanical equipment. Since 2005, the development momentum of the sheet metal industry has been very rapid, and the position and weight in the market are becoming more and more important, not only to our company. In addition to the huge economic benefits,…

Shenzhen stamping machine selection specifications in the selection of stamping type, must also determine the equipment specifications, mold design work. The selection of the best-selling Shenzhen stamping machine is also determined according to the technical plan and calculation results, coordination of the mold number, and equipment parameters. Of course, there are still many people who…

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español