ABS plastic (Acrylonitrile Butadiene Styrene) Specific gravity: 1.05 g/cm3 Mold shrinkage: 0.4-0.7% Molding temperature: 200-240℃ Drying conditions: 80-90℃ 2 hours Material performance 1. Good overall performance, high impact strength, chemical stability, and good electrical properties 2.Good weldability with 372 plexiglass, made of two-color plastic parts, and can be chrome-plated and painted. 3. There are high…

Parameters: Material name: TPU Printing temperature: 210-225° Material density: 1.2g/cm³ Material hardness: 95HSA Elongation: 400% Print bottom plate temperature: room temperature -50° Bubble: no bubbles Characteristic: 1: High transparency-high resilience, suitable for printing shoes, insoles and other soft models 2: High mechanical strength-high wear resistance and aging resistance 3: Waterproof and moisture permeability, cold proof,…

Parameters: Material name: PA (nylon) Printing temperature: 240-280° Material density: 1.01±0.05g/cm³ Water absorption: easy to absorb water Tensile strength: ≥50MPa Elongation at break: ≥150.0% Bubble: no bubbles characteristic: 1: High purity-the material uses high-quality nylon particles, non-toxic, non-irritating, healthy and safe, will not block the nozzle, and will not cause insufficient extrusion 2: High precision-the…

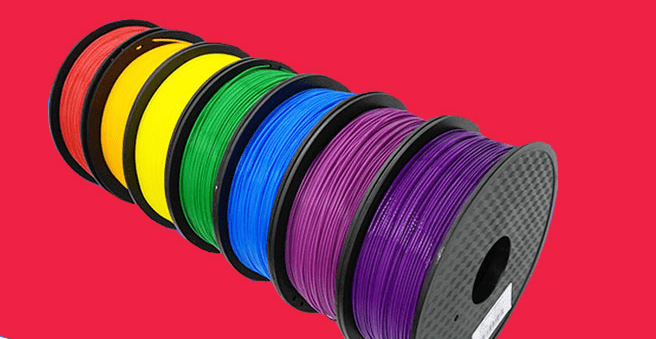

Parameters: Material name: ABS Printing temperature: 220-240° Material density: 1.04±0.2g/cm3 Water absorption: 1% Tensile strength: ≥43MPa Elongation at break: ≥10.0% Bubble: no bubbles Characteristic: 1: High strength-stronger than PLA, impact resistance, heat resistance, chemical resistance, and difficult to degrade, more suitable for manufacturing 2: High precision-the wire diameter tolerance is controlled within 0.02mm, which is…

Tolerance table of injection plastic parts (according to SJ1372 standard) size mm Accuracy class 1 2 3 4 5 6 7 8 Tolerance mm ~3 0.04 0.06 0.08 0.12 0.16 0.22 0.32 0.48 >3 ~ 6 0.05 0.07 0.08 0.14 0.18 0.28 0.35 0.56 >6 ~ 10 0.06 0.08 0.10 0.16 0.20 0.32 0.40 0.61…

PLA physical parameters Material: PLA Color: red, white, black, green, blue, gray, transparent, army green, fuchsia, etc. Printing temperature: 170-220° Density: 1.25±0.03g/cm³ Water absorption: 0.5% Tensile strength: ≥60MPa Elongation at break: ≥3.0% Impact strength: 0.16J/M PLA material features: 1, PLA, or polylactic acid, is a new type of biodegradable material, refined from renewable plant resources,…

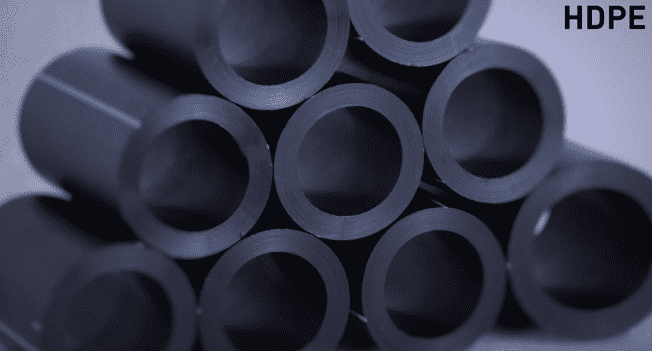

High Density Polyethylene (HDPE for short) is a non-polar thermoplastic resin with high crystallinity. The appearance of the original HDPE is milky white, and the thin section is translucent to a certain extent. PE has excellent resistance to most domestic and industrial or chemical preservation properties, and will produce chemical and acid resistant fermentation products….

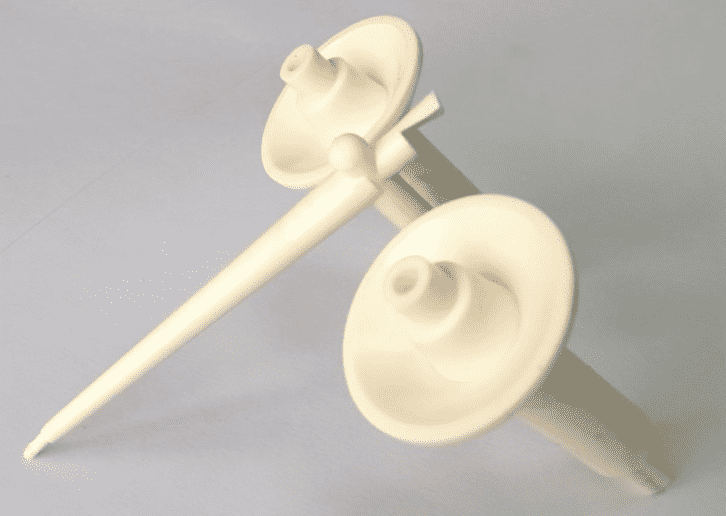

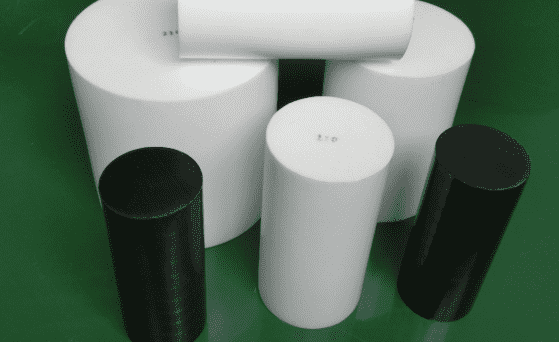

From cookware to aerospace engineering, the applications and classification of Teflon have no bounds. It is well known for its strength, excellent temperature resistance, and non-sticky nature. However, this material is more complex than it may sound. The Teflon coatings are also very useful in protecting the material from stickiness. Different types of Teflon…

PVC is the abbreviation of polyvinyl chloride and its English name is Polyvinylchloride. The main component is polyvinyl chloride. It is bright in color, corrosion-resistant, strong and durable. It is reinforced by adding some toxic auxiliary materials such as plasticizers and anti-aging agents in the manufacturing process. Its heat resistance, toughness, ductility, etc., so its…

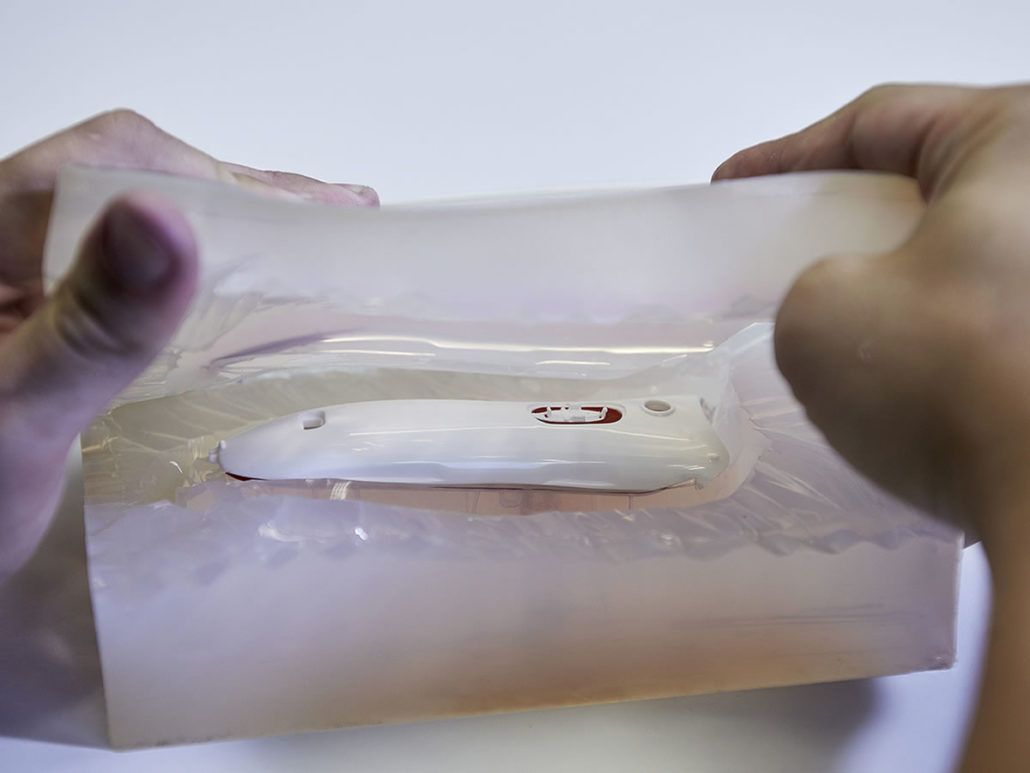

1. The mold silicone and the curing agent are evenly stirred. The appearance of the mold silica gel is a flowing liquid, the component A is silica gel, and the component B is a curing agent. For example, 100 g of silica gel is added, and 2 g of a curing agent is added (Note:…

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español