Key points: Analyze the product (specific material bai performance, appearance requirements, whether du undercut, whether there is a special process, whether the zhi type is defective) Difficulties: Improve mold life, control costs (the easiest to process), and have a comprehensive grasp of the best appearance of the product. Simply put, it is the design. The…

The quality of the tool, spindle speed, cutting speed, cutting fluid will all affect. Imported carbide knife, high speed

The difference between hard anodizing and ordinary anodizing: Advantages of aluminum alloy hard oxidation: 1. The surface hardness of aluminum alloy after hard oxidation can reach up to about HV500. 2. The oxide film thickness is 25-250um. 3. Strong adhesion, according to the oxidation characteristics of hard oxidation: 50% of the formed oxide film penetrates…

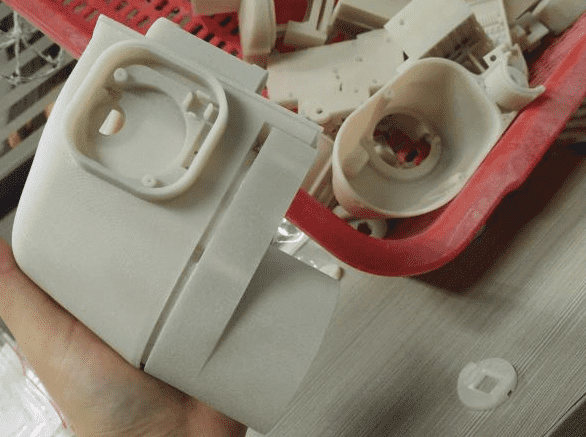

Vacuum injection molding, namely vacuum compound mold, also called silicone compound mold, needs to be applied to silicone mold. The castable is defoamed, mixed, preheated, and molded under vacuum conditions, and the process of secondary curing and molding is performed in a thermostat at 60℃-80℃ for 2-3 hours, and the imitation of silicone compound molding…

3D printing, like laser forming technology, uses layered processing and overlay molding to complete 3D solid printing. The printing process of each layer is divided into two steps. First, spray a layer of special glue on the area that needs to be formed. The glue droplets themselves are small and difficult to spread. Then spray…

Advantages of wire cutting: 1. CNC wire cutting processing is contour cutting processing, no need to design and manufacture forming tool electrodes, which greatly reduces processing costs and shortens the production cycle. 2. Directly use electric energy for pulse electric discharge machining. The tool electrode and the workpiece are not in direct contact, and there…

1. Before tapping, find out the specifications of the threads according to the requirements of the drawings and select the taps of the same specifications. 2. Check whether the size of the bottom hole meets the specifications and whether the bottom hole is chamfered. 3. When tapping the thread, the calibration part of the tap…

Acrylic display stands, as a relatively high-quality plexiglass, have been widely used in the production of various crafts and display stands. Among them, there are about six types of acrylic display rack manufacturing processes: 1. Mosaic method: According to the design drawing, use a laser cutting machine to cut the different colors of the acrylic…

Electroplating is the process of plating a thin layer of other metals or alloys on the surface of certain metals using the principle of electrolysis. According to the composition of the coating, the electroplating process can be divided into five categories: chrome plating, copper plating, cadmium plating, tin plating, and zinc plating. 1. Chrome plating…

In recent years, PP fiber reinforced materials have developed rapidly in the modified plastics industry, and most of the glass fiber reinforced materials used in the automotive field are PP substrates. With the improvement of plastic modification technology and the needs of the development of the automotive industry, the development trend of long glass fiber…

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español