1. Different thickness: The thickness of hard oxide is thicker than that of ordinary oxide. Generally, the thickness of ordinary oxide film is 8–12 um, and the thickness of hard oxide film is generally 40-70 um. 2. Different hardness: Hardness: Normal oxidation is generally HV250-350, and hard oxidation is generally HV350-550. 3. the temperature is…

Brass Brass is a copper-zinc alloy, and brass composed of copper and zinc is called ordinary brass. Material advantages: It has high strength, high hardness, and strong chemical resistance. The mechanical properties of cutting are also outstanding. Brass has strong wear resistance. Special brass is also called special brass. It has high strength, high hardness…

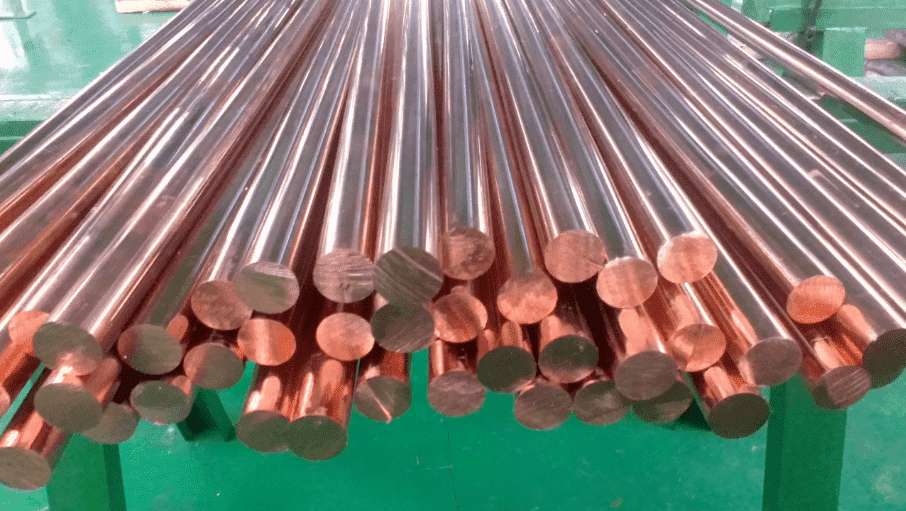

Pure copper (also known as red copper) is a ductile metal with excellent electrical conductivity. The surface is rose red. It is not pure copper, it contains 99.9% copper, and some other elements are added to improve the surface and performance. Material advantages: It has good electrical conductivity, thermal conductivity, ductility, deep drawing and corrosion…

7075 aluminum alloy 7075 aluminum alloy is a cold-treated forging alloy with high strength, far better than mild steel. 7075 is one of the most powerful alloys commercially available. Material advantages: General corrosion resistance, good mechanical properties and anode reaction. The finer grains make the deep drilling performance better, the tool wear resistance is enhanced,…

6061 aluminum alloy is a high-quality aluminum alloy product produced by heat treatment and pre-stretching process. Although its strength can not be compared with 2XXX series or 7XXX series, its magnesium and silicon alloy characteristics are many. Material advantages: It has excellent processing performance, excellent welding characteristics and electroplating, good corrosion resistance, high toughness and…

1. The number of tooling is greatly reduced, and complex tooling is not required for processing parts with complex shapes. If you want to change the shape and size of the part, you only need to modify the part processing program, which is suitable for new product development and modification. 2. The processing quality is…

In recent years, 5-axis CNC CNC machining centers have been widely used in various fields. Whenever people encounter special-shaped and complex parts, five-axis linkage technology is undoubtedly an important means to solve such problems. More and more manufacturers tend to look for 5-axis processing equipment to meet high-quality processing. Do you really understand CNC 5-axis…

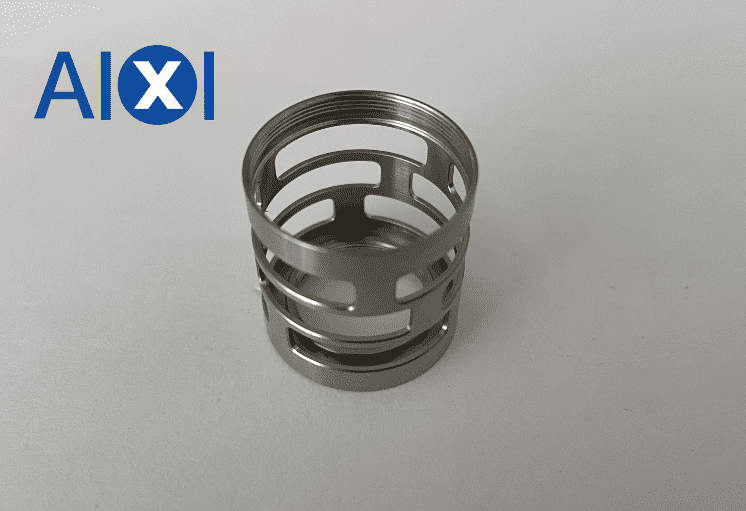

1 Thread milling method CNC machining centers can use thread milling tools to directly process threads. This is also a common processing solution in the market. It is widely used in more complex thread processing and large-hole thread processing operations, and the advantages are also obvious. The thread milling method under the CNC machining mode…

CNC machining stainless steel products CNC milling stainless steel CNC turning stainless steel CNC drilling stainless steel 440C stainless steel: can be oil-quenched to achieve the maximum hardness, heat-treated to 58-60 HRC 420 stainless steel: resistance to mild corrosion, high heat resistance, increased strength 2205 duplex stainless steel: the highest strength and hardness, can withstand…

We have full inspection and routing inspection during CNC milling machining aluminum parts. We have modern and precision equipment to ensure we can make the highest precision aluminum milled parts(focus on 0.01-0.02mm tolerance). We have rich CNC machining experience and professional engineers, and international sales team have rich tade experience . We can offer inspection…

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español