What is aluminum anodizing? Anodizing is a relatively simple electrochemical process that has been used for nearly a century to increase the thickness of native oxide layers on aluminum surfaces. Aluminum Anodizing is a strong and durable finish that maintains the beauty and natural metallic luster of aluminum while enhancing its natural ability to withstand…

Aluminum anodization is actually an electrolytic oxidation process. After the aluminum profile is oxidized, a protective film will be formed on the surface. This film can improve the decorative effect and corrosion resistance of aluminum products. attach great importance to. The following will introduce the principle of aluminum anodizing process. The aluminum alloy is used…

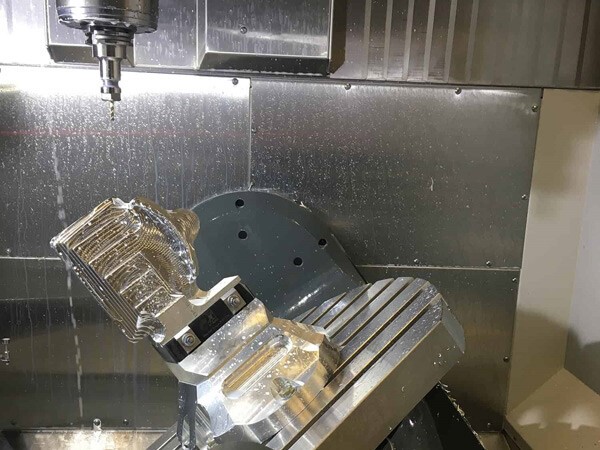

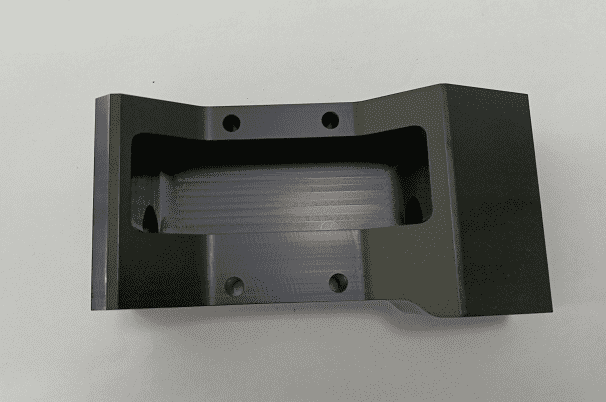

CNC precision machining can manufacture a variety of complex parts with high precision. Machines and tools that can be mastered through CNC machining include lathes, grinders, and mills. CNC or computer numerical control allows extremely specific control over the positioning, speed, blending, feed rate and other precision aspects of the manufacturing process for a particular…

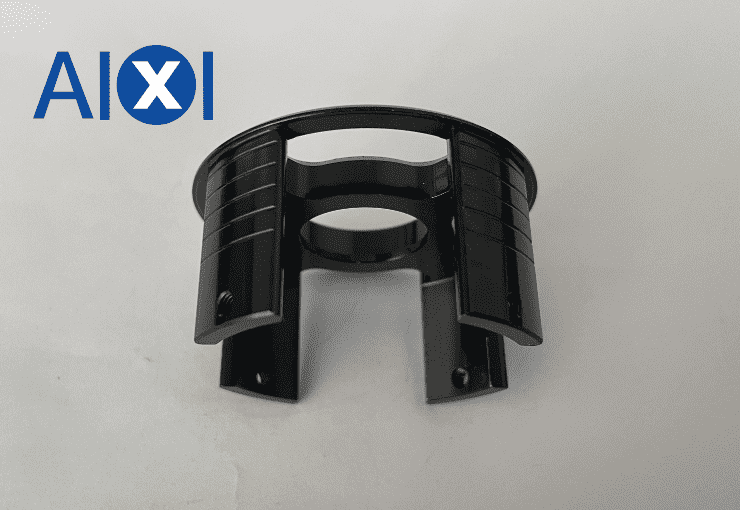

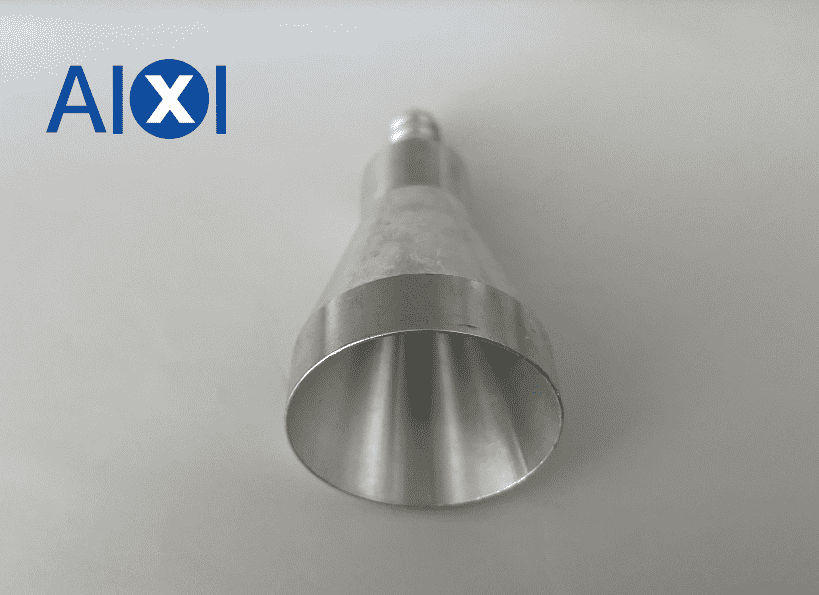

AIXI Hardware will start the new year work today. AIXI wish new and old customers a better business in the new year. CNC Machining 3D Printing AIXI’s Products AIXI Rapid Ship

The reason why CNC precision machining is called precision machining is that its processing procedures and processing requirements are very high, and the precision requirements of products are also very high, and the machining accuracy of precision parts includes: position accuracy, dimensional accuracy, style accuracy, etc., The components that affect the precision of precision parts are…

In the process of processing, every process is very critical. If there is a process that is not operated in time due to carelessness in the process of processing, it is very likely to immediately endanger the final actual effect of the product. Therefore, in the process of work, the operating staff must be very…

During the machining and cutting process, the CNC lathe is subjected to the action of the cutting force, and the elastic deformation occurs in the direction of the force, which is what we often call the phenomenon of letting the knife. Corresponding measures should be taken on the tool to deal with such deformation. The…

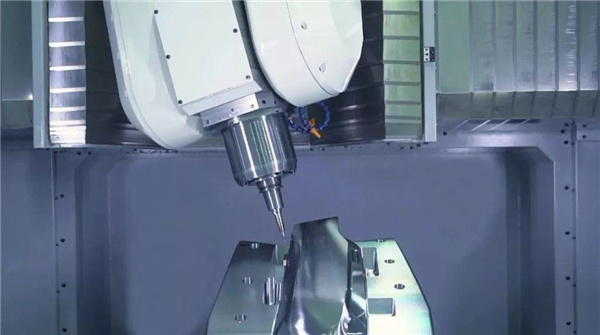

Five-axis machining is not a new term at present, and it has been widely used in enterprise practice. The following is a brief introduction to the reasons why the five-axis machining center is so popular. First, the economy of the five-axis machining center. 1: The five-axis machining center can clamp multiple workpieces at one time,…

Many people are not clear about the CNC machining process, so the CNC processing factory will briefly introduce what the CNC machining process is. The composition of the entire CNC process includes product analysis-graphic planning-process planning-pathway generation-pathway simulation-pathway output-processing-inspection. 1. Product analysis should obtain certain composition information and some specific processing requirements. 2. Graphic planning…

45 steel 45 steel is the name in GB, also called “oil steel”, this steel has higher strength and better machinability. Material advantages: It has high strength and good machinability. After proper heat treatment, a certain degree of toughness, plasticity and wear resistance can be obtained. The material source is convenient. It is suitable for…

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español