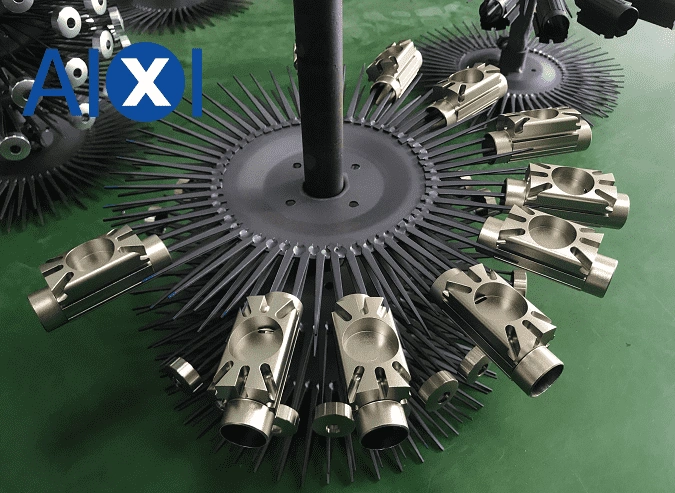

CNC Lathe Parts Rapid Services / Custom CNC Turned Parts Company – AIXI

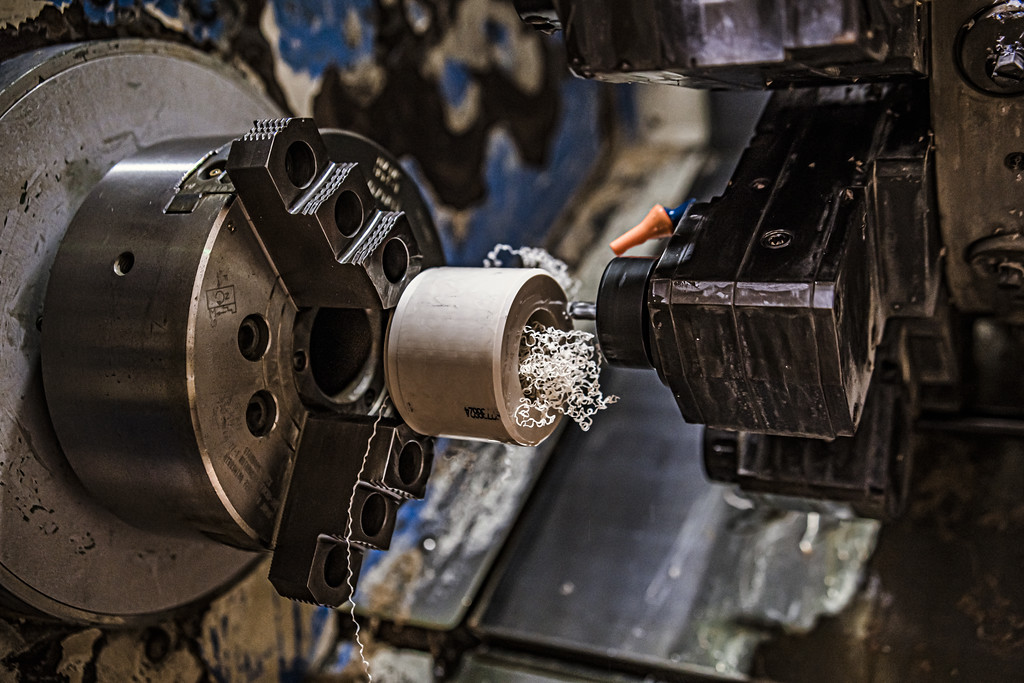

Due to its high speed, CNC lathe processing can always handle large orders and deliver quickly. AIXI is an experienced CNC turning service supplier. Our factory has CNC lathes and turning centers, which can quickly provide high-quality CNC-turned parts of metal and plastic. Common CNC turning manufacturing materials are aluminum, stainless steel, brass rods or tubes, plastics ABS, POM (Delrin), PA (Nylon), PTFE, etc., used for rapid prototyping and small batch production. Send us the CAD file, and you will get a professional online CNC quotation. For turning parts with a length of less than 300mm and a diameter of less than 100mm, we can quickly deliver samples within two days and then deliver them worldwide via DHL in 2 to 3 days. Therefore, if you order CNC-turned parts from our factory, you can receive a real product within five days. If your product includes the milling part, we can deliver it quickly within three days.

Contact Us

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español