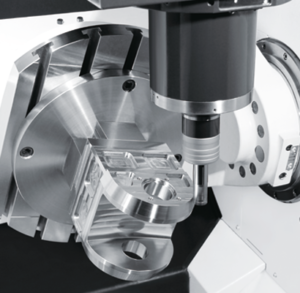

In recent years, 5-axis CNC CNC machining centers have been widely used in various fields. Whenever people encounter special-shaped and complex parts, five-axis linkage technology is undoubtedly an important means to solve such problems. More and more manufacturers tend to look for 5-axis processing equipment to meet high-quality processing. Do you really understand CNC 5-axis machining?

5-axis machining

To truly understand AIXI CNC 5-axis machining, first, what we have to do is to understand what a 5-axis CNC machine tool is. As the name suggests, it means adding two to the three common linear axes X, Y, and Z. Rotation axis. The two rotating shafts of the A, B, and C three axes have different motion modes to meet the technical requirements of various products. Integrating the various five-axis CNC machining machines currently on the market, although their mechanical structure is in various forms, there are mainly the following forms.

Two rotating coordinates directly control the direction of the tool axis (double swing head form)

The two coordinate axes are at the top of the tool,

But the rotation axis is not perpendicular to the linear axis (pitch type swing head type)

Two rotating coordinates directly control the rotation of the space (double turntable form)

The two coordinate axes are on the worktable,

But the rotation axis is not perpendicular to the linear axis (pitch type work table)

Two rotating coordinates act on the tool one,

One acts on the workpiece (one swing and one turn)

Having seen these five-axis CNC machining machines, I believe we should understand what and how the five-axis CNC machining machines move. However, with such a diversified machine tool structure, what characteristics can it exhibit during machining? Compared with traditional three-axis machine tools, what are the advantages? Next, let us take a look at the luminous points of CNC 5-axis machining.

Features of CNC 5-axis machining machine

Speaking of the characteristics of CNC 5-axis machining tools, it is necessary to compare with traditional three-axis equipment. Three-axis machining equipment is more common in production, and there are several forms such as vertical, horizontal and gantry. Common processing methods include end milling cutter end edge processing and side edge processing. The profiling processing of ball-end knives and so on. But no matter which form and method have a common feature, that is, the direction of the tool axis remains unchanged during the machining process, and the machine tool can only realize the rectangular coordinate of the tool in space through the interpolation of the three linear axes of X, Y, and Z. Sports in the department. Therefore, when facing the following products, the disadvantages of the low efficiency of the three-axis machine tool, the poor surface quality and even the inability to be processed are exposed.

Compared with three-axis CNC processing equipment, 5-axis processing machine tools have the following advantages:

1. Maintain the best cutting condition of the tool and improve the cutting conditions

2. Effectively avoid tool interference

3. Reduce the number of clamping, and complete five-sided processing in one clamping

4. Improve processing quality and efficiency

5. Shorten the production process chain and simplify production management

6. Shorten the new product development cycle

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español